The pressure-enthalpy diagram (log p-h diagram) and the basic process

Refrigeration Basics

The pressure-enthalpy diagram and the basic process

1. The pressure-enthalpy diagram (log ph diagram)

The thermodynamic properties of a refrigerant are often represented in a pressure-enthalpy diagram. Here, the logarithm of pressure is plotted as a function of enthalpy, with the various thermodynamic properties as parameters (see Figure 1). The main components are:

◆ The thick line (boiling line)

Contents

Jobs

Mounting

Mechanic/Welder (m/f/d) at GEA

We are looking for three mechanics/welders (m/f/d) at our Berlin location.

Image

GEA Refrigeration Germany GmbH

Berlin, Germany

Fulltime

Project management refrigeration technology

Commercial Employee Order Processing in Engineering (m/f/d)

To strengthen our team, we are looking for a commercial employee to handle engineering projects as soon as possible.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fitter refrigeration technology

MTA Refrigeration Technician (m/f/d) in Customer Service for Baden-Württemberg

To strengthen our team for the Stuttgart region, we are looking for you as a Refrigeration Technician (m/f/d) for our customer service.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fulltime

Get in Touch with the Author

If you have any questions or would like additional information, the author of this article is happy to assist you. Simply use the options below to get in touch directly.

Related Products

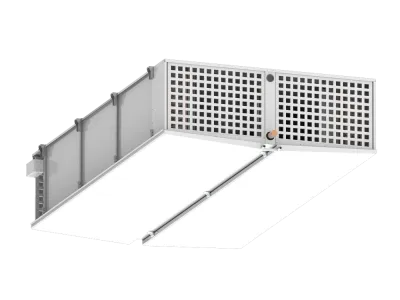

Image

with a draught-free airflow and a low noise level

Image

Industrial air cooler (stainless steel/aluminium) - quiet and powerful

Image

Double Sided Blowing High performance air cooler for cold rooms CDH

Image

LLZ, MLZ and MLM scroll compressors for standard and compact commercial refrigeration applications

Image

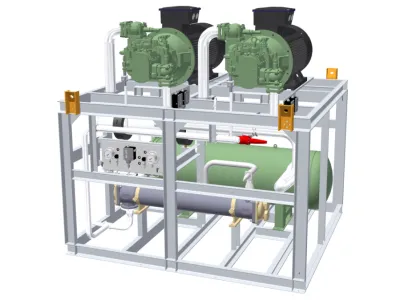

NH3 cooling plant solutions as single compressor units or as a parallel system with two open screw compressors

Cooling capacity MT: 70-1469 kW

Cooling capacity LT: 28-568 kW

Cooling capacity MT: 70-1469 kW

Cooling capacity LT: 28-568 kW

Image

The HK series is designed for high pressure. The compressor can compress gas up to 50 bar.

Related Articles

Drop-In Refrigerants - Definition and Application

Using Drop-In Refrigerants as an Environmentally Friendly Alternative

MAK Value – Maximum Workplace Concentration

The MAK value determines the safe concentration of substances in workplace air and protects individuals from health risks.

What is subcooling?

Reducing energy costs and ensuring the longevity of the system with subcooling.

The refrigeration cycle

The refrigeration cycle and its components explained simple

Basics Of Thermodynamics

Describes the transport and conversion of various forms of energy in systems.

condensing units Installation instructions

General information and practical tips for using Danfoss OptymaTM condensing units are given below. OptymaTM condensing units represent a complete range of units with hermetic Danfoss reciprocating compressors. The design of this series corresponds to the needs of the market. In general, to give an overview of the program, each subsection is divided into the different hermetic compressors mounted on the condensing units.

The refrigeration manufacturer

Mechatronics technician for refrigeration technology

Why refrigeration technology?

In certain areas of application, refrigeration systems are more energetic than conventional heating systems.

Energy optimization of refrigeration systems

Energy optimization of refrigeration systems