Ammonia has a reputation for being dangerous in the conventional refrigeration industry.

Refrigerant

R717 Ammonia as a Refrigerant

History of Ammonia in the Refrigeration Industry

Ammonia (NH₃ or R717) is the refrigerant that was first used in vapor compression machines around 1870. It has thus been used in large-scale refrigeration and industrial systems for more than 100 years.

Key Data

NH₃ has the lowest TEWI (Total Equivalent Warming Impact = direct greenhouse effect of the

Contents

Product Ad

Image

GEA Purger ist ein Entlüftungsgerät, das die Konzentration von Luft und anderen nicht kondensierbaren Gasen reduziert

Jobs

Mounting

Mechanic/Welder (m/f/d) at GEA

We are looking for three mechanics/welders (m/f/d) at our Berlin location.

Image

GEA Refrigeration Germany GmbH

Berlin, Germany

Fulltime

Project management refrigeration technology

Commercial Employee Order Processing in Engineering (m/f/d)

To strengthen our team, we are looking for a commercial employee to handle engineering projects as soon as possible.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fitter refrigeration technology

MTA Refrigeration Technician (m/f/d) in Customer Service for Baden-Württemberg

To strengthen our team for the Stuttgart region, we are looking for you as a Refrigeration Technician (m/f/d) for our customer service.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fulltime

Get in Touch with the Author

If you have any questions or would like additional information, the author of this article is happy to assist you. Simply use the options below to get in touch directly.

Related Products

Image

Low operating costs and extremely low maintenance are the key parameters.

Image

SABROE® - Building Customer Trust for a Better World - SABROE is a registered trademark of Johnson Controls

Image

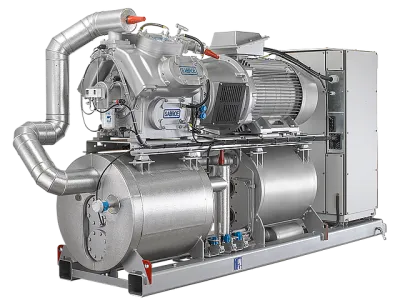

Im industriellen Prozess werden mit Ammoniak arbeitende Kälteanlagen, insbesondere solche für die Produktion und Lebensmittelverarbeitung, aber auch im Marinebereich, starke und leistungsfähige Kompressoren benötigt.

Related Articles

Refrigerant Overview and Properties

Discover the latest refrigerants for efficient and eco-friendly cooling!

Drop-In Refrigerants - Definition and Application

Using Drop-In Refrigerants as an Environmentally Friendly Alternative

Azeotropic and Zeotropic Refrigerants: Properties and Differences

Learn the key differences between azeotropic and zeotropic refrigerant blends

Refrigerant R513A - Drop-In Alternative for R134a

R513A was developed as a replacement refrigerant for R134a.

MAK Value – Maximum Workplace Concentration

The MAK value determines the safe concentration of substances in workplace air and protects individuals from health risks.

Flammable Refrigerants - ATEX in the Refrigeration Industry

The refrigeration industry is increasingly adopting flammable refrigerants like propane, making compliance with ATEX directives for safety and explosion protection essential.

Propane (R290) as a Refrigerant - Safety Regulations and Requirements

R290 is an environmentally friendly but flammable refrigerant. Its use therefore requires special safety measures and compliance with legal regulations.

DIN EN 378 – Guidelines for Refrigeration Systems and Heat Pumps

The EU standard governs the safety, operation, and environmental impact of refrigeration systems and heat pumps.

The F-Gas Regulation in the EU 2024 and R32

The EU's F-Gas Regulation 2024 does not impose any restrictions on the continued operation of air conditioning systems and heat pumps using R32 refrigerant.