Hydrocarbons as a refrigerant - isobutane (R600a) and propane (R290)

In addition to environmental friendliness, hydrocarbons offer cost advantages in heating / cooling and freezing. As a common substitute for hydrofluorocarbons (now considered to be harmful to the environment), HCs can handle the oils and other components found in many existing systems. In addition, they are inexpensive and result in a significantly better energy efficiency, which is reflected in lower operating costs.

A hydrocarbon (HC) is a chemical compound between hydrogen and carbon. These elements occur in nature, such as in high concentration in crude oil. As innovative, non-toxic refrigerants, hydrocarbons are an environmentally friendly alternative to ozone-depleting fluorocarbons (CFC / HCFC / HFC).

HCs are flammable, but the use of propane (R290) for cooking and heating is common practice. Certain rules for the safe use of such materials are necessary and accepted by all users.

Several HC types can be used as refrigerants, but isobutane (R600a) is the most commonly used HC in household refrigerators and freezers. Propane (R290) is used more in commercial heat pumps, air conditioners, and refrigerators and freezers.

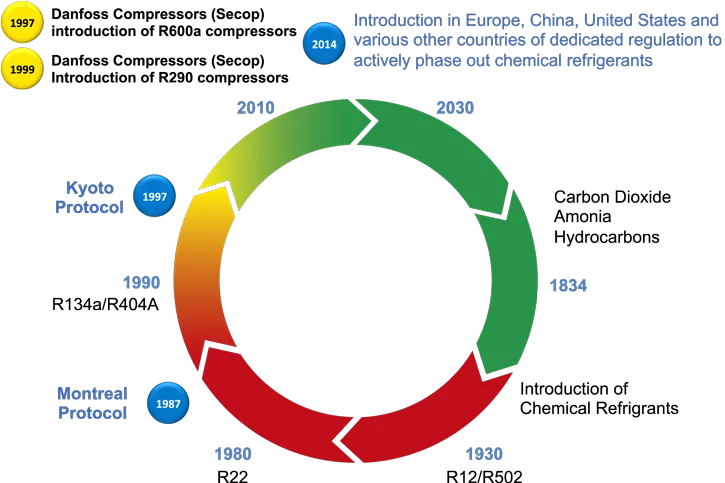

History of the refrigerants

Important data

- China, January 2030 - 60% reduction in HFC emissions (previously no specific regulations known)

- China, January 2025 - 25% reduction in HFC emissions (no specific regulations known so far)

- Europe, January 2022 - HFC ban with GWP> 150 in commercial refrigerators and freezers

- USA, January 2021 - Ban on R134a in air conditioning systems of vehicles

- USA, January 2020 - HFC ban in all MBP applications & standalone LBP systems

- Europe, in January 2020 - HFC ban with GWP> 150 in-air air conditioning systems

- Europe, January 2020 - HFC ban with GWP> 2500 in commercial refrigerators and freezers

- USA, January 2019 - HFC ban in vending machines and all "MBP" refrigeration systems (<2200 BTU / h)

- USA, January 2017 - Ban on HFCs in supermarket systems

- USA, July 2016 - HFC ban in all retrofit refrigeration systems

- Europe, January 2015 - Limitation of HFC quantities for import and production (+ tax increases)

- Europe, January 2015 - HFC ban with GWP> 150 in household refrigerators and freezers

- Worldwide January 2015 - Complete ban on R12 and start of phase-out phase R22

Hydrocarbons and the environment

HC refrigerants are not considered an ozone layer destroyer, and most species have a global warming potential (GWP) of magnitude 3. By comparison, the synthetic refrigerant R404A (for which HCs are a common substitute today) has been astronomical high GWP of 3260.

Systems with HC refrigerants play a dual role in reducing levels of harmful greenhouse gases. Firstly, the direct emissions of greenhouse gases (GHG) emissions are significantly reduced thanks to the low GWP value of HCs. For example, in a typical supermarket, between 5 and 10% of the total local refrigerant is released into the atmosphere - using HCs as a substitute refrigerant reduces gas emissions by many tonnes per year.

On the other hand, the physical properties of HC-based systems - lower liquefaction point, thermodynamic advantages and higher coefficient of performance (COP) - combine to make energy efficient operation possible. For example, in an air conditioning system, using propane (R290) as a replacement for HFC-134a results in at least 80% reduction in greenhouse gas emissions.

Further advantages of HCs are the low-cost availability as a by-product in the extraction and processing of oil and gas as well as the fact that the achievable energy savings by HC systems has already been proven in many studies. Against this backdrop, hydrocarbons have long been proven to be a viable substitute for fluorocarbons and other environmentally harmful refrigerants.

Hydrocarbon Technologies

The importance of HCs has so far been most apparent in household and freezer units, where the Isobutane (R600a) refrigerant, which was first used in the Greenfreeze refrigerator for the first time, is now in use worldwide. In commercial refrigeration systems it is now the same, in supermarkets and many other places mainly propane (R290) is used as a replacement for the ozone depleting refrigerant. It is similar in the field of air conditioning. There you will find HCs in residential and office buildings. In addition, certain groundwater heat pumps use energy-saving propane (R290).

HC systems use the same cooling circuit as those with synthetic refrigerants. Propane (R290) is as refrigerant compatible with the equipment and equipment designed for the traditional - the ozone depleting - synthetic refrigerant R22; therefore, it is a direct replacement that is far superior in terms of performance to its synthetic competitor.

In summary, the HC technology has the following advantages:

- no destructive effect on the ozone layer

- significantly lower emissions of greenhouse gases

- low global warming potential and thus smaller contribution to global warming

- higher energy efficiency

- easy use

- Changeover with very low investment

Safety requirements

HCs are subject to international safety guidelines and laws because of their fire hazard. Their use is limited to a capacity of 150g per system, but exceeding this value in Europe is officially permitted under certain favorable conditions. All manufacturers of HC systems must adhere to safety rules, and their service personnel must understand and apply the prescribed procedures for the safe handling of HC. Government safety regulations demand leakage simulation tests and strict regulations apply to the insulation of electrical components in the vicinity of refrigerant flows. In addition, many domestic and commercial appliances, such as domestic refrigerators, freezers, heat pumps, commercial refrigeration and compressors, are subject to international safety regulations.

Market Overview

Isobutane (R600a) refrigeration systems today dominate the domestic refrigeration and freezer markets entirely in the European single market, 50% in China and good sales figures throughout the first world. Propane (R290) and other hydrocarbons are well established in commercial refrigeration and similar developments are already underway in air conditioning. An important future market is the USA. The influence of world brands such as McDonalds is not yet in sight. When HC systems establish themselves here, there is a great need for the necessary components.

Flammable refrigerant R600a and R290

R600a and R290 are hydrocarbons. These refrigerants are flammable and are only permitted for use in equipment that meets the requirements specified in the current revision of EN / IEC 60335-2-24. (To cover potential risks arising from the use of flammable refrigerants).

Consequently, R600a and R290 are the only refrigerants that can be used in household appliances because they meet the above standards. R600a and R290 are heavier than air and the concentration on the ground is always highest. R600a may only be stored and transported in approved containers and must be handled according to valid guidelines.

To perform service and repairs on R600a and R290 systems, service personnel must be trained accurately and properly.

This includes knowledge of tools, transport of the compressor and refrigerant as well as the relevant regulations and safety precautions.

No open fire when working with refrigerant R600a and R290!

Conversion of refrigerant R12 or R134a R600a is not allowed as the refrigerators are not approved for use with flammable refrigerant and electrical safety has not been tested to existing standards. The same applies to conversions of refrigerant R22, R502 or R134a R290. Secop compressors for flammable refrigerants R600a and R290 are equipped with a yellow warning label.

Typical applications

Household refrigerators and freezers

- bottle cooler

- Ice machines and refrigerated counters

- Commercial refrigeration equipment

- beer cooler

- Soda Fountain

- Dehumidifiers

- Heat pumps

R600a as replacement of R134a in household refrigerators

In 1993, the Greenfreeze refrigerator was introduced, which was developed by Greenpeace in collaboration with the East German manufacturer Foron (formerly VEB dkk Scharfenstein). It could be proved that R600a, although flammable, does not cause problems in a household refrigerator.

Greenpeace's campaign has put so much pressure on traditional manufacturers (Bosch-Siemens, Liebherr, Miele, AEG, Electrolux, Bauknecht) that they have decided to speed up the launch of R600a and phase out the recently launched R134a!

Also in 1993, Danfoss Compressors (Secop) introduced compressors for R600a.

Today, more than 700 million R600a domestic refrigerators are used worldwide.

By 2020, 75% of global production will be based on R600a.

"With kind permission of Secop GmbH"