BAC Baltimore Balticare GmbH

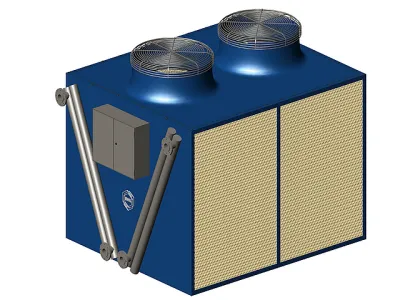

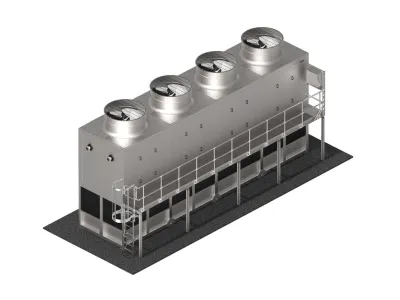

BAC Balticare S1500E cooling tower

S1500E features:

cross-flow, axial fan, induced draft principle

Extremely low noise level

- A choice of low-noise axial fans and whisper-quiet fans for minimal ambient noise.

- BACross filling guides the water calmly and without water splashing noises to the pool.

- One-sided air intake and a quieter tower rear for more noise-sensitive areas.

- Try our XES1500E range with smaller motors for extremely low noise levels .

- Factory engineered, tested and dimensioned sound attenuation is available at the air intake to further reduce operating noise.

Unprecedented energy savings

- Evaporative cooling for system-wide energy savings at lower operating temperatures.

- Axial fans require half the energy of similar centrifugal fan units.

- Save pump kW! Less pump head for this gravity water distribution system. During periods of reduced load, weir dams partially close the hot water basin, saving pump energy .

- BACross fill - factory configured for maximum water/air contact and low airside pressure drop for optimal cooling tower efficiency with limited energy consumption.

- Highly efficient fan motors

- Multiple fan motor system covers independent fan motor and drive assembly per fan. In the event of a fan failure, the other fan(s) will continue to operate.

- XES1500E series with smaller motors to reduce power consumption with the same cooling capacity.

Low maintenance and hassle free inspection

- Unprecedented safe and convenient access. Inspection and maintenance of the tower while standing and without crawling.

- The S1500E has a spacious service channel (inside) and offers easy access for inspection/service .

- Access via a large hinged door. With optional internal walkway : there is no need to drain a basin to inspect the interior of the unit or the fill pack.

- Inspection of the water distribution (hot water basin and nozzles) outside the unit, possible during operation .

- Optional water distribution tray covers prevent debris from accumulating inside the unit.

- You can easily inspect and clean the core of the BACross fill sheet by sheet without disassembling. BACross construction reduces fouling. Optional telescopic packing supports for easy blade replacement.

- The fill includes integral drift eliminators tested and certified by Eurovent.

- Self-cleaning cold water basin and fill above sloping basin to flush out dirt and debris.

- Fans are easily accessible from inside and outside.

- Optional cleanout port helps remove silt and sludge from cooling tower basin.

- Suction strainer with removable anti-turbulence hood.

- Optional sump suction prevents accumulation of sediment in the cold water basin.

- Various corrosion -resistant materials, for example the unique Baltibond hybrid coating , for guaranteed long service life.

- Optional engine removal davit for hassle-free engine replacement.

Excellent hygiene control

- Proper hygiene inspection without shutting down the unit .

- Easy to clean and inspect S1500E towers to reduce hygiene risks due to bacteria (Legionella) or biofilm inside.

- Self-cleaning cold water basin and fill above sloping basin to flush out dirt and debris.

- BACross fill for reduced fouling and easy cleaning sheet by sheet without disassembly.

- The fill includes integral drift eliminators tested and certified by Eurovent.

- Combined air intake shields block sunlight to prevent biological growth inside the tower, filter the air and prevent water from splashing outside.

- Optional water distribution tray covers prevent debris from accumulating inside the unit.

- Optional cleanout port helps remove silt and sludge from cooling tower basin.

- Optional sump suction prevents accumulation of sediment in the cold water basin.

Ideal replacement device

- One-sided air inlet and outlet fits most installation conditions.

- S1500E are ideal replacement devices . Small fan motors and low spray pressure allow existing control cabinet to be reused.

- S1500E cooling towers are factory assembled and shipped in 1 or 2 pieces to reduce the overall size and weight and allow for easy on-site assembly of the pieces with a smaller crane.

Reliable operation all year round

- Optimum device condition thanks to inspection during operation.

- Proven winter operation without freezing .

- The thermal performance of the S1500E cooling towers is tested and certified by Eurovent .

- Multiple fan motor system covers independent fan motor and drive assembly per fan. In the event of a fan failure, the other fan(s) will continue to operate.

- Various corrosion -resistant materials, for example the unique Baltibond hybrid coating , for guaranteed long service life.

S1500E properties

Cross flow, axial fan, induced draft principle

power range

8 - 215 l/s 40% more power

water distribution

Variable flow gravity

Maximum water inlet temperature

55 °C standard packing 60 °C with alternative packing

Typical applications

- Medium air conditioning and industrial applications

- Replacement of counterflow and crossflow devices

- Tight installation conditions

- Installations requiring a single air intake

S1500E

overview

- working principle

- design features

- options and accessories

- Technical specifications