WRI - Vortex Sintered Evaporative Cooling Tower

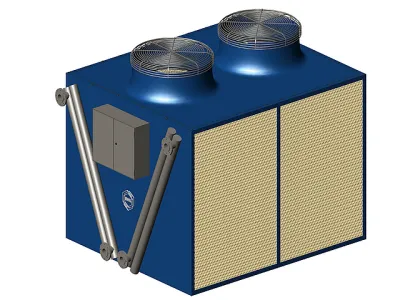

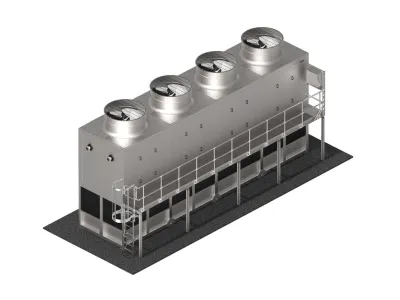

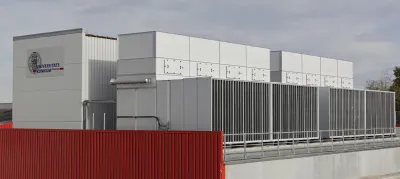

The closed cooling tower is primarily used where high demands are placed on the quality of the cooling water, for example, in the cooling of machines with narrow cooling channels.

Your Benefits

- Secure system separation

- Good efficiency

- Compact

Applications

- Indoor installation in buildings or machine rooms

- Outdoor installation

- Building air conditioning

- Industrial process cooling

Operating Principle

The cooling of process heat is achieved by the evaporation of the natural refrigerant water, with a counterflow heat and mass transfer occurring between the cooling water and the ambient air. In the closed-circuit evaporative cooler, the ambient air does not come into direct contact with the cooling water: The water flows through a closed pipe coil system that forms the primary circuit for cooling a consumer. Clean water that does not form deposits is always circulating. To cool the primary circuit, the pipe coil system is wetted with recirculated water from the secondary circuit and cooled by evaporation.

Primary Circuit

- Hot-dip galvanized smooth tube heat exchanger made of steel (optionally also in stainless steel) with a high exchange surface allows for safe operation.

Secondary Circuit

- The water distribution of the spray water is done through a pipe system made of galvanized steel (for ERI: stainless steel) to which plastic hollow cone nozzles are attached. Easy removal is ensured by plug connections (in the stainless steel version) or screws (in the galvanized version). The water distribution is done through an external pump and stainless steel riser pipe.