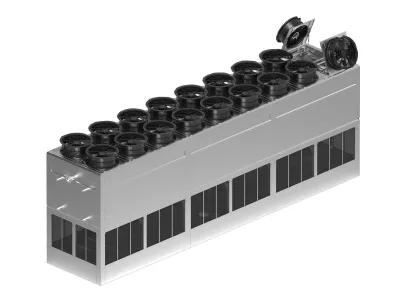

BAC Balticare Polairis Evaporative Condensers

Extremely reliable

-

The design of the Polairis TM evaporative condenser incorporates all of the experience BAC has acquired over the past several decades installing thousands of VXC units installed worldwide since 1978.

-

Fan drive systems are located inside the unit, in the dry air , which prevents condensation and eliminates corrosion problems and premature failures.

-

Direct drive fans eliminate potential mechanical failures .

-

Multiple, individually driven fans guarantee redundancy .

-

Baltibond hybrid plastic coating for maximum equipment life, with corrosion resistance that meets SST 304L.

-

Dry operation possible.

energy efficient

-

Evaporative condensers achieve the lowest condensing temperatures, thereby minimizing the energy consumption of the entire system .

-

Up to 50% savings with the energy efficient backward curved centrifugal fans compared to standard centrifugal fans.

-

EC motors offer excellent efficiency that exceeds IE4 requirements. The integrated electronics of the EC motors allow variable speed control with significantly reduced energy consumption compared to AC motors with VFD.

Minimal maintenance and easy inspection

-

Direct drive fans require no maintenance at all .

-

The DiamondClear TM design* offers self-cleaning continuous operation. The need for maintenance is minimized through the use of fully inclined surfaces, a constant effect of the falling spray and high water velocities .

-

Collection basin occupies a fraction of the unit's footprint, exposing it to higher levels of turbulence. This, along with the significantly reduced volume (25% reduction over traditional evaporative condensers) , reduces chemical usage and cleaning requirements .

-

Unprecedented accessibility to the basin, drives and fans in the dry section via the man-sized access door at ground level.

-

The water distribution is easily accessible from the outside .

-

Baltibond Hybrid plastic coating for a smooth finish that makes interior cleaning easier .

Excellent hygiene

-

The DiamondClear TM design* offers self-cleaning continuous operation. When stationary, the inclined surfaces are completely emptied, avoiding stagnant water and the risk of contaminant sedimentation.

-

A fully encased reservoir eliminates all sunlight penetration, which discourages biological growth .

-

Baltibond Hybrid plastic coating for a smooth surface that reduces biofilm development .

-

The floor is fully sloped towards the discharge for easy cleaning – even in the dry part.

-

Water treatment connections are provided as standard.

-

The access door is located in the dry area, eliminating any risk of leakage .

Optimized for transport and hassle-free installation

-

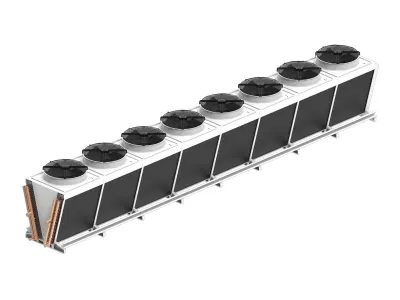

Installation costs are reduced as units are supplied in two factory assembled pieces with a rigid base frame that guarantees squareness for easy field assembly.

-

Minimal freight costs with 2.4m wide units that fit in standard trucks.

-

Fans are pre-wired to a control panel to eliminate time-consuming on-site wiring. The integrated electronics of the EC motors eliminate the need for external VFDs, electronic filters and shielded cables.

-

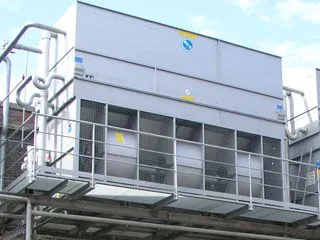

One-way air intake allows installation in confined spaces and next to solid walls .

-

Pressure capability of fans allows indoor installation with duct system.

-

Quiet, backward-curved centrifugal fans reduce the need for soundproofing.

Ultra Quiet

-

Quiet, backward curved centrifugal fans are standard.

-

One-sided air intake allows the quiet device to be set up in noise-sensitive areas .

-

Silencer is available for the most stringent sound requirements .

Polairis properties

-

Counter flow, backward curved centrifugal fan, pressure principle

-

Tube bundle design according to PED 2014/68/EU

power range

850 - 1890 kW (for single cell models, nominal R717 kW)

Typical applications

-

Industrial cooling applications with a focus on reliability, energy efficiency and minimal maintenance

-

Confined installation conditions and noise-critical installations

-

Dry operation in winter

overview

- working principle

- Construction features

- options and accessories

- Special requirements

- Technical specifications