The liquefaction of the refrigerant and heat recovery in a refrigeration system

Thermokey Deutschland GmbH

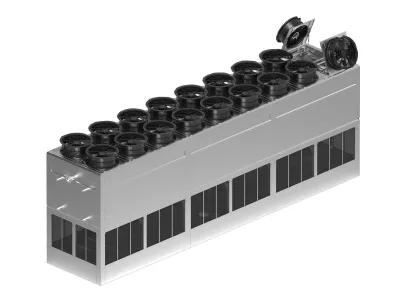

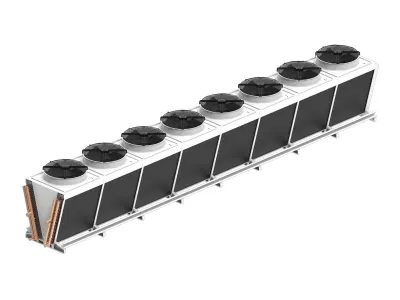

ThermoKey condenser Turbo-J

Refrigerant condenser TURBO-J with axial fans

Refrigerant condenser TURBO-J with axial fans

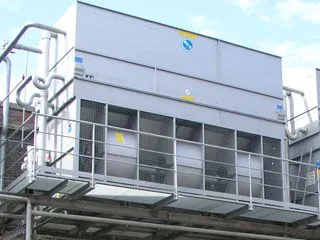

THERMOKEY condensers of the "TURBO-J" series are used for refrigerant condensation in refrigeration machines and liquid coolers in refrigeration and air-conditioning technology where, due to noise problems, the heat must be dissipated separately on the outside. The devices are available for the usual refrigerants R134a, R 404A, R407C, R410A and R507 with copper tubes and for ammonia applications (NH3) with stainless steel tubes.

Low energy consumption and low noise emissions were the goals when developing the new "TURBO-J" series. The essential factors are an optimized smooth fin, new pipe geometries assigned to the refrigerants used and the arrangement of the fans in combination with different heat exchanger lengths and thicknesses.

The result:

- Maximum performance with a small footprint. Cooling capacity with nominal data from 100kW to 1,900kW. Subdivision up to four cooling circuits possible.

- Axial fans from ZIEHL-ABEGG or EBM with two speeds, suitable for stepless speed control through phase control or frequency converters are available, alternatively EC fans for energy-optimized applications and noise-relevant applications.

- Fans with a diameter of 900 mm in four different volume levels are used. The number of fans per device can vary between 1 and 18 depending on the design data.

- Great stability and torsional rigidity (particularly with large unit lengths) of the heat exchangers arranged in a V-shape thanks to the galvanized steel frame, completely powder-coated in RAL 7035.

- Strict compliance with the applicable European standards. Performance and noise data tested by TÜV Bayern. The specified performances and sound pressure levels are subject to the ENV 1048 standard.

- Simple device selection with the multilingual design software "ARCHIMEDE". In addition to all the important technical data, the corresponding device sketch is also created. Accessories and special equipment can be selected in price information.

A complete range of accessories and special equipment rounds off the "TURBO-J" series:

- Speed controller using phase angle control or frequency converter from Ziehl-Abegg.

- Connection boxes and control cabinets with main switch, also possible in versions according to customer or end customer requirements.

- Aluminum, copper or stainless steel fins. Aluminum slats can also be epoxy-coated to protect against environmental influences.

- Copper tubes for the usual refrigerants or stainless steel (V4A) for NH3 applications.

- Subcooling circuits.

- AFS system, pre-cooling of the intake air by adiabatic humidification. Depending on the design point, the inlet temperature of the cooling air is reduced by 8 to 10 K - this means that the units can be smaller, power reserves can be stored or the condensation temperature can be reduced even at high outside temperatures to reduce the compressor power consumption.