The design is generally determined by the mass flow rate and not by the pipe diameter.

Components

We explain

What to Consider with Check Valves

The medium in which check valves are used is crucial. Check valves in liquid lines have different spring loads compared to those in compressed gas and suction gas lines. The designs can vary from manufacturer to manufacturer and must be coordinated beforehand.

In compressed gas lines, check valves are generally determined by the mass flow rate and not by the pipe diameter. Typically, they are one to two sizes smaller.

If check valves in gas lines are oversized, it can lead to the valve slamming open and shut, potentially causing damage. This is particularly true during partial load operation of a refrigeration system, where the mass flow rate through the check valve decreases.

Contents

Product Ad

Image

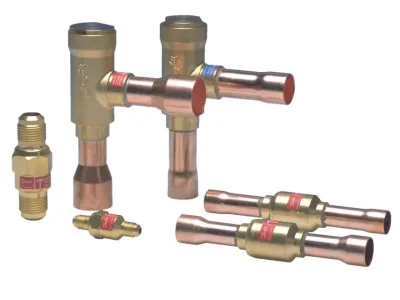

NRV and NRVH can be used in liquid, suction and hot gas lines in refrigeration and air conditioning systems with fluorinated refrigerants.

Jobs

Mounting

Mechanic/Welder (m/f/d) at GEA

We are looking for three mechanics/welders (m/f/d) at our Berlin location.

Image

GEA Refrigeration Germany GmbH

Berlin, Germany

Fulltime

Project management refrigeration technology

Commercial Employee Order Processing in Engineering (m/f/d)

To strengthen our team, we are looking for a commercial employee to handle engineering projects as soon as possible.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fitter refrigeration technology

MTA Refrigeration Technician (m/f/d) in Customer Service for Baden-Württemberg

To strengthen our team for the Stuttgart region, we are looking for you as a Refrigeration Technician (m/f/d) for our customer service.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fulltime

Get in Touch with the Author

If you have any questions or would like additional information, the author of this article is happy to assist you. Simply use the options below to get in touch directly.

Related Products

Image

AWP service valves are suitable for use in refrigerant circuits for industrial refrigeration systems.

Image

Safety valves dependent on back pressure, spring-loaded.

Image

Safety valves not dependent on back pressure, spring-loaded.

Image

AWP control valves with metal bellows are suitable for use in refrigerant circuits in industrial refrigeration systems.

Image

Angle shut-off valve for refrigeration applications, available from DN15 to DN150.

Image

Straight-through shut-off valve for refrigeration applications, available from DN15 to DN150.

Related Articles

12°C – Hot Gas Defrosting for Evaporators

Efficient Defrosting in Industrial Freezer Warehouses

Ammonia - Key Operating Points

Overview of Critical Design Parameters in Industrial Refrigeration Systems Using Ammonia

Drop-In Refrigerants - Definition and Application

Using Drop-In Refrigerants as an Environmentally Friendly Alternative

Azeotropic and Zeotropic Refrigerants: Properties and Differences

Learn the key differences between azeotropic and zeotropic refrigerant blends

Refrigerant R513A - Drop-In Alternative for R134a

R513A was developed as a replacement refrigerant for R134a.

Flammable Refrigerants - ATEX in the Refrigeration Industry

The refrigeration industry is increasingly adopting flammable refrigerants like propane, making compliance with ATEX directives for safety and explosion protection essential.

Propane (R290) as a Refrigerant - Safety Regulations and Requirements

R290 is an environmentally friendly but flammable refrigerant. Its use therefore requires special safety measures and compliance with legal regulations.

The F-Gas Regulation in the EU 2024 and R32

The EU's F-Gas Regulation 2024 does not impose any restrictions on the continued operation of air conditioning systems and heat pumps using R32 refrigerant.

Impact on R407C - The Revised F-Gas Regulation 2024

The updated F-Gas Regulation (EU) No. 517/2014 has significant implications for systems using the refrigerant R407C