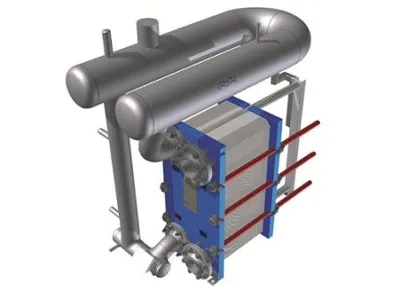

ESK Liquid Separator (FA)

Refrigerant compressors draw in the refrigerant in vapor form and compress it to the necessary conditions for liquefaction. However, due to system and temperature conditions, situations may arise where refrigerant in a more liquid form is returned to the compressor. These instances, known as liquid slugging, result in the following damage to the compressor:

- Destroyed suction valves

- Seal breakage

- Bearing damage

- Piston and rod breakage

- Destroyed pressure valves

ESK Liquid Separators are built based on the time-tested injector principle, which prevents the intake of liquid even when the separators are filled. Especially in compact systems with insufficient suction gas superheat dT < 7 K (backflow of unevaporated liquid droplets), issues related to oil/refrigerant behavior can cause oil pressure problems and significant reductions in system performance. ESK Liquid Separators protect compressors and systems from liquid slugging and operational disruptions. Their use is strongly recommended in the following criteria:

- Compound systems

- Liquid displacement

- Transport cooling

- Flooded evaporators

- Hot gas defrosting

- Switchable systems

- Container cooling

- Suction gas superheat < 7K

- Heat pump systems