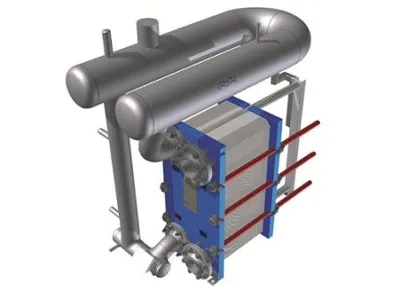

Alfa Laval U-Turn

Alfa Laval U-Turn is designed to use the best of Alfa Laval plate heat exchanger technology. The standalone U-Turn can be mounted on top of the compatible plate heat exchanger. It can cover ammonia capacities from 200 to 1400 kW at an evaporating temperature of 0 °C and from 50 to 500 kW at an evaporating temperature of -40 °C.

The module offers an effective and compact installation with fewer vertical heights and smaller overall dimensions than any other solution.

Key Features

- Compact dimensions

- Shorter height and length allow for on-site installation without disassembly

- No additional support is required as the U-Turn separator is fully supported by the plate heat exchanger

- Easy maintenance as both sides of the plate heat exchanger are fully accessible.

- All ammonia connections are on the same side, which simplifies installation

- Integrated oil drain

- Stainless steel that ensures corrosion resistance and requires no surface treatment

Ready to install

For standard reasons, the U-Turn module will be delivered within a short time. It is a fully functional module from a single source and bears the CE stamp as well as PED (Pressure Equipment Directive) approval.

How it works

The U-Turn module opens a new chapter on vaporization. To find out why and how it works, please read the main features and watch our video at the bottom of the page

- It ensures efficient separation - by using four different separation methods.

- The short vertical ammonia driving columns enable small temperature approaches and high system efficiency.

- The gliding support allows for thermal expansion so that there are no thermal stresses.

- Significant oil pot volume in the standard version sufficient for manual emptying

- Separation by drop size 0.15 mm

- The cut-off is 25% plus a nominal diameter

- Maximum separation gas velocity is limited to 60% of the re-entrainment velocity to avoid liquid being reintroduced into the gas stream.

- Additional safety distance from 180 ° U-bend.