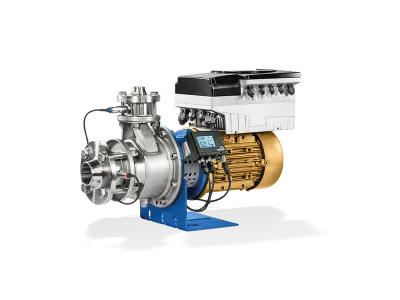

Wilo-VeroLine-IP-E

Special features/product benefits

- Energy savings through integrated electronic power adjustment

- Optional interfaces for bus communication through pluggable IF modules

- Easy operation with green button technology and display

- Integrated dual pump management

- Integrated full motor protection (KLF) with trigger electronics

Type

Electronically controlled glanded single pump in inline design with flange connection and automatic power adjustment

Deploy

Conveying of heating water (according to VDI 2035), cold water and water-glycol mixtures without abrasive substances in heating, cold water and cooling systems.

Equipment/Function

Operating modes

- Δp-c for constant differential pressure

- Δp-v for variable differential pressure

- PID Control

- Manual operation (n=constant)

Manual control level

- Green button and display

Manual Functions

- Setting the differential pressure setpoint

- Setting the speed (manual operation)

- Operating mode setting

- Set pump ON/OFF

- Configuration of all operating parameters

- Error acknowledgment

External control functions

- Control input "Priority Off"

- Control input "External pump exchange" (only effective in double pump operation)

- Analog input 0-10 V, 0-20 mA for manual operation (DDC) and remote setpoint adjustment

- Analog input 2-10 V, 4-20 mA for manual operation (DDC) and remote setpoint adjustment

- Analog input 0-10 V for actual value signal from the pressure sensor

- Analog input 2-10 V, 0-20 mA, 4-20 mA for pressure sensor actual value signal

Reporting and display functions

- Collective error message SSM

- Collective operating message SBM

Data exchange

- Infrared interface for wireless data exchange with IR monitor/IR stick

- Slot for Wilo IF modules (Modbus, BACnet, CAN, PLR, LON) for connection to the building automation

Backup Features

- Full motor protection with integrated trigger electronics

- Access lock

Double pump management (double pump or 2 x single pump)

- Main/standby operation (automatic fault switchover)

- Main/standby operation, pump exchange after 24 hours

- Addition mode

- Additional operation (efficiency-optimized peak load switching on and off)

Scope of delivery

- pump

- Installation and operating instructions

Type code

Example

IP-E 40/160-4/2-R1

IP-E

In-line pump with electronic control

40

Nominal size DN of the pipe connection

160

nominal impeller diameter

4

Motor nominal power P2 in kW

2

Number of poles

R1

Version without pressure sensor

Specifications

- Permissible temperature range -20 °C to +120 °C

- Power connector

-

- 3~400V ±10%, 50Hz

- 3~380V -5% +10%, 60Hz

- Protection class IP 55

- Nominal size DN 32 to DN 80

- Max. Operating pressure 10 bar (special version: 16 bar)

Materials

- Pump housing and lantern: EN-GJL-250

- Impeller: PPO-GF30

- Wave: 1.4021

- Mechanical seal: AQEGG; other mechanical seals on request

Description/Construction

Single-stage low-pressure centrifugal pump in inline design with

- Mechanical seal

- Flange connection

- Drive with integrated electronic speed control