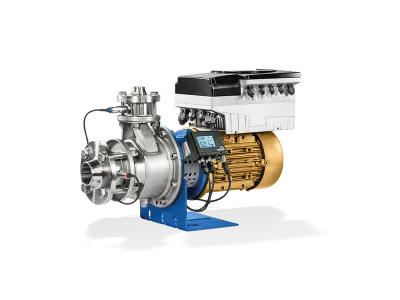

Wilo-SiFlux

Special features/product benefits

- Quick and easy installation thanks to the pre-installed system. This minimizes troubleshooting.

- Energy-saving: Operation in the partial load range according to current needs.

- Reliable system thanks to coordinated components.

- Compact design, easy access to all components.

- Everything from a single source. Less need for clarification in procurement.

Type

Highly efficient, fully automatic, ready-to-connect multi-pump system for realizing large flow rates in heating, cold water and cooling systems. 3 to 4 electronically controlled dry-running inline pumps of the VeroLine-IP-E or CronoLine-IL-E series connected in parallel. One pump each as a reserve pump. Incl. Smart Controller SCe.

Deploy

For pumping heating water (according to VDI 2035), water-glycol mixtures and cooling and cold water without abrasive substances in heating, cold water and cooling systems.

>

Equipment/Function

- 3-4 pumps per system of the VeroLine-IP-E or CronoLine-IL-E series, of which 2 or 3 pumps are in operation, 1 standby pump

- IE2 standard motor

- Automatic pump control via Smart Controller SCe

- Parts in contact with media are corrosion-resistant

- Base frame galvanized steel with height-adjustable vibration dampers for structure-borne noise insulation

- Distributor steel, corrosion-resistant coated

- Flanges PN 16 according to EN 1092-2 on the pressure and suction side for connection to the piping system

- Pre-assembled seals on pressure and suction side

- Shut-off fittings on the suction and pressure side

- Backflow preventer on the pressure side

- Differential pressure sensor

- Pressure gauges on the pressure and suction side

Scope of delivery

- Multi-pump system Wilo-SiFlux

- Installation and operating instructions Wilo-Siflux

- Installation and operating instructions pump

- Installation and operating instructions switching device

Type code

Example:

Wilo-SiFlux-21-IP-E 40/120-1.5/2-SC-16-T4

SiFlux

Product Family

21

Version (21= 2+1 pumps: 2 pumps in operation, 1 standby pump)

IP-E 40/120-1.5/2

Electronically controlled, 2-pole inline pump of type IP-E, nominal diameter of the pipe connection DN 40, nominal impeller diameter 120 mm, 1.5 kW nominal motor power P2

SC

Switching device type SC...

16

max. Operating pressure in bar

T4

Power supply 3~400 V, 50 Hz

Specifications

- Pump type: VeroLine-IP-E or CronoLine IL-E

- Number of pumps: 2 + 1 or 3 + 1 (2 or 3 pumps in operation, 1 standby pump each)

- Power supply: 3~230/400 V, 50 Hz ±10%

- Motor efficiency class: IE2

- Permitted Pumping media: heating water (according to VDI 2035), water-glycol mixtures, cooling and cold water (other media on request)

- Flow rate: 50 to 360 m3/h

- Head: 45 m

- Storage temperature: -10°C to +50°C

- Permitted Ambient temperature: 0°C to +40°C

- Permitted Media temperature: 0°C to +100°C

- Pipe connections manifold: DN 125 to DN 300

- Flanges: PN 16, drilled according to EN 1092-2

- Max. Permissible operating pressure: 10 bar for VeroLine-IP-E pumps, 16 bar for CronoLine-IL-E pumps