Thermal expansion, deflection and corrosion resistance

Applications

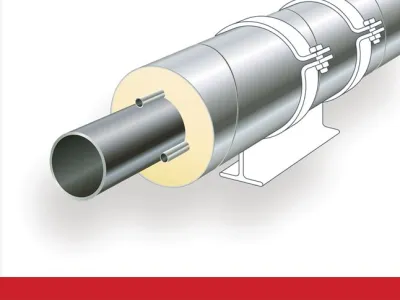

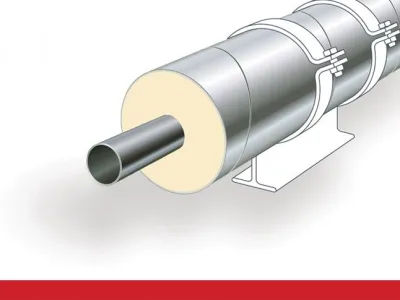

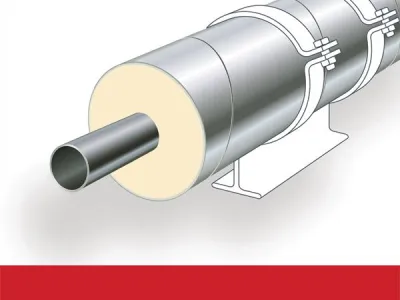

Pre-insulated piping

Thermal expansion of pre-insulated pipes

The expansion behavior of pre-insulated pipes under thermal stress corresponds to that of the uninsulated pipe. Although this is an insulated composite pipe, the proportion of the medium pipe outweighs the structure of the composite system. The movement of the product-carrying pipe is imposed on the outer

Contents

Service Ad

Wholesaler

Refrigeration and air conditioning

rff Rohr Flansch Fitting

Carl-Zeiss-Straße 21

28816 Stuhr

Germany

Jobs