Lubricating oils are liquid media that, depending on the friction conditions in the friction point, serve as an intermediate and mostly as a construction element.

Operating materials

Basics of lubricating oils

In the first part of our training Basics of lubrication technology, we wrote about friction and wear as well as the various types of lubricants. In this part, we want to provide information on the basics of lubricating oils. It is to give you an overview of what lubricating oils are, what their structure and composition is, what types of oils

Contents

Product Ad

Image

With our Klüber Summit product brand, we offer you a number of fully synthetic product lines, as well as Klüber Summit RHT-68, a paraffin-based mineral oil with a modern formulation.

Jobs

Mounting

Mechanic/Welder (m/f/d) at GEA

We are looking for three mechanics/welders (m/f/d) at our Berlin location.

Image

GEA Refrigeration Germany GmbH

Berlin, Germany

Fulltime

Project management refrigeration technology

Commercial Employee Order Processing in Engineering (m/f/d)

To strengthen our team, we are looking for a commercial employee to handle engineering projects as soon as possible.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fitter refrigeration technology

MTA Refrigeration Technician (m/f/d) in Customer Service for Baden-Württemberg

To strengthen our team for the Stuttgart region, we are looking for you as a Refrigeration Technician (m/f/d) for our customer service.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fulltime

Get in Touch with the Author

If you have any questions or would like additional information, the author of this article is happy to assist you. Simply use the options below to get in touch directly.

Related Products

Image

With our Klüber Summit product brand, we offer you a number of fully synthetic product lines, as well as Klüber Summit RHT-68, a paraffin-based mineral oil with a modern formulation.

Image

IKET Ltd

Pohlmann pocket book of refrigeration technology

Image

Korn, Dieter

Efficient operation of refrigeration systems

Image

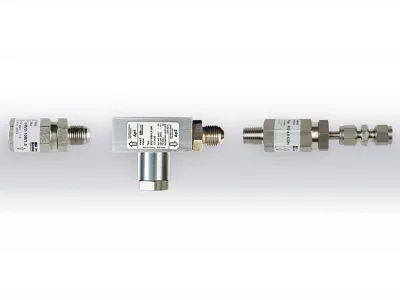

The combined oil separator-collectors are specially designed for use in high-pressure oil control systems.

Image

When compressors are operated in a network, oil level regulators are attached to the compressor to control the oil level.

Image

In order to be able to supply the oil from the collector to the compressors in sufficient quantities, a pressure difference must be built up between the oil collector and the compressor crankcase.

Related Articles

condensing units Installation instructions

General information and practical tips for using Danfoss OptymaTM condensing units are given below. OptymaTM condensing units represent a complete range of units with hermetic Danfoss reciprocating compressors. The design of this series corresponds to the needs of the market. In general, to give an overview of the program, each subsection is divided into the different hermetic compressors mounted on the condensing units.

Higher energy efficiency

Higher energy efficiency - an imperative from the current sustainability megatrend.

Basics of lubricating greases

What is a lubricating grease, how are lubricating greases structured, what types of lubricating greases are there, advantages in practice

Basics of lubricating oils

Lubricating oils are liquid media that, depending on the friction conditions in the friction point, serve as an intermediate and mostly as a construction element.

Basics of Tribology

Tribology is a branch of science and engineering dealing with the interaction of surfaces moving relative to one another

HFO/HFKW-blends as alternatives to HFKWs

The decision to use the low GWP refrigerant R1234yf in car air conditioning systems has meanwhile also initiated the development of alternatives for other mobile applications and stationary systems.

Viscosity of refrigeration oil

Viscosity of refrigeration oil

Refrigeration oils

The main task of a Refrigeration oils is the lubrication of machine parts