WITT Evaporator units

Evaporator units

You decide, we have the solution.

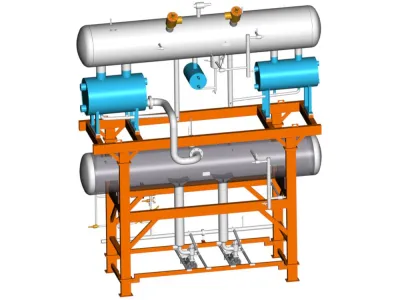

WITT evaporator units are always the right solution when the refrigerant should be limited to the machinery room and a secondary refrigerant pumped to the coolers (indirect refrigeration). WITT installs either fully welded or semi-welded evaporators in evaporator units with a flooded design. Of course, all heat exchangers from recommended brand names. The selection of a suitable heat exchanger is not only depending on the application and operating conditions. We are happy to support you.

According to your individual requirements you decide quite flexibe any additional equipment for your evaporator unit, i.e.:

- Stop valves

- Overflow valves

- Service valves

- Automatic fast acting valves

- HR and HS high-pressure float regulators

- NGX maximum level switch

- Stand pipe with level control

- Differential pressure piping incl. pressure gauges and

- WITT oil management

The positioning of connections on the pressure vessel for inlet and outlets can be chosen according to your needs taking into account the technical feasibility

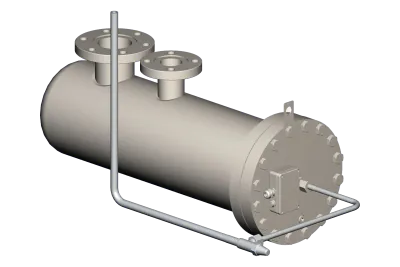

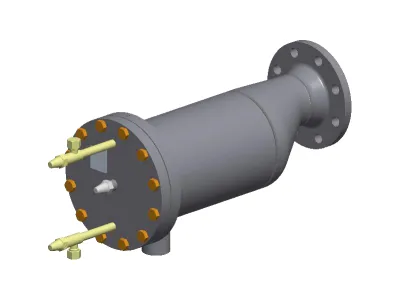

SAV – standard separator evaporator unit

he SAV is a high-capacity, standardised evaporator unit, consisting of a semi-welded Alfa Laval plate evaporator combined with a WITT high-efficient separator type HAM and the necessary accessories.

The dimensions, weight and connections of the separator unit have been standardised as per AD2000 regularity and the PED Module H1. This reduces necessary time for planning of the system and we provide you with a fast delivery time of five to six weeks.

Whether you need the evaporator on the left or right hand site or you would like to position the valves according to your needs, it is your choice. We can even supply you the evaporators for the SAV15 separately with flange connections.

All SAV stations are supplied with

- lockable stainless steel stand pipe with G1" connection

- WITT NGX overflow protection

- Compressor suction valve AVR corner (AWP)

- Injection valve AVR corner (AWP)

- Connection flange F DN15

- Manometer/pressure sensor/service connection

- Oil dome with valve DN 32

- 2 x Manual oil drain EA10

- 1 x 1 x Service valve EA10

- Optional PARKER safety valve unit

- Optional RTK fill-level probe

- Optional WITT BDP oil recovery unit