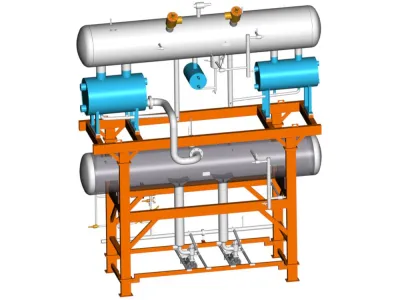

WITT ECO open flash Economiser

ECO open flash Economiser

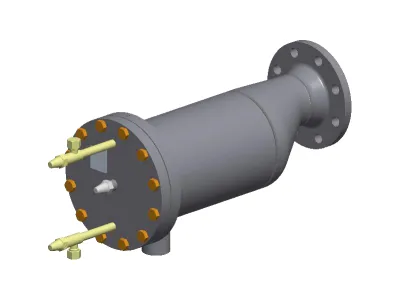

Size reduction of plant components at screw compressor systems, multi-stage expansion for high differential pressures.

The WITT Economiser (ECO) collects the refrigerant that has condensed in the condenser unit after it was drained from a HR high-pressure float regulator in its housing. Inside the ECO housing liquid is separated from the gas at intermediate pressure. The liquid refrigerant drained and expanded via a further highside float regulator inside the ECO to the surge drum on the low-pressure side. The flash gas that has been separated in the ECO at intermediate pressure is returned to the ECO port of the compressor and introduced back into the compression process.

This form of open flash economiser operation reduces the compressor load so the compressor can be sized smaller. It also means that the low-pressure surge drum can be reduced in size.

When an extension of refrigeration capacity is required the WITT economizer is a good option: with the reduction of flash gas, that is returned to the compressor and does not effect the low pressure surge drum, the refrigeration capacity of the surge drum is increased.

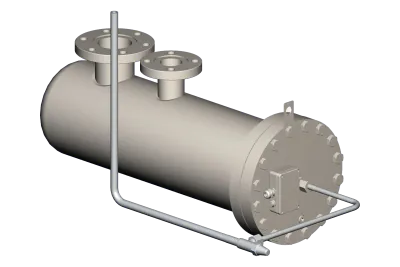

The standard scope of supply of a WITT Economiser includes:

- A fitted HR high-pressure float regulator with stop valves

- WITT stop valves at the inlet and outlet connections for gas and liquid

- An EA 10 GB L drain valve

- An EE 6 L vent valve, in front of an EA 10 GB L

- Combined threaded connection G ½“/G ¼“ for safety valve

- NGX maximum level switch (packed loose)

- Steel frame including wooden supports and mounting brackets

Accessories

- Inlet/outlet connections without stop valves

- Individual inspection by TÜV or other test bodies

- Special executions upon request