FX highside float regulators

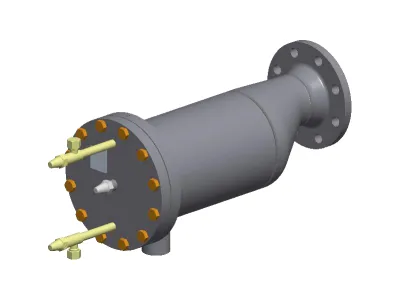

Developed for the natural refrigerants NH3 and CO2, the new FX series of highside float regulators sets new standards in industrial refrigeration technology. The compact design in 2 sizes, each with 4 capacity stages, enables the FX series to achieve capacity peaks of up to 2,646 kW at a stillstand pressure of PN 40 bar.

The modular design allows the float to be customised to meet individual customer requirements. It can be equipped with service valves, stop valves, an internal low-pressure nozzle or a control valve as an external low-pressure nozzle or with a venting device. Options can be selected individually to ensure optimal expansion of the refrigerant from the high-pressure to the low-pressure side without any problems.

The mechanically operated WITT highside float regulators helps you to save energy while offering a high level of safety without a need for additional electrical cables and controls.

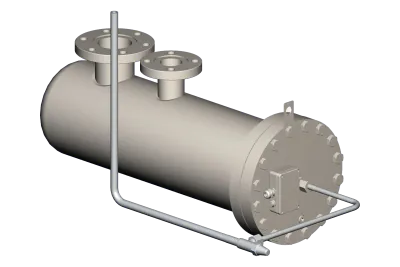

The principle is as simple as it is effective. When the refrigeration capacity increases will the liquid level in the highside float regulator rise and the refrigerant expands via the entirely mechanical operated float valve orifice opening. Due to this expansion (pressure loss) in the outlet opening there will be a liquid-vapour mixture behind the HP float regulator that is drained back to the surge drum. A high pressure receiver is normally not required.

The continuous expansion of the highside float valve eliminates pressure fluctuations and flash gas is reduced. Therefore the electrical power consumption of the compressor is reduced as well.

The flooded operation with highside float valves can take advantage of lower ambient temperatures during the colder seasons with lower condensation temperatures, independent of the control system. And with a 5K lower condensation temperature you already save about 13% electrical energy consumption.

Effective hot gas defrost with highside float regulators

The WITT highside float regulator will increase the efficiency of your hot gas defrost of evaporators. Since the highside float regulator will drain only liquid refrigerant and gas cannot pass by, energy loss of hot gas by-pass is eliminated. Compared to other defrost methods up to 50% electrical energy is saved this way.