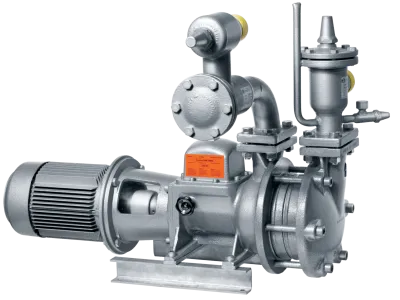

Refrigerant pump CAM

CAM

The flow is controlled by the one behind the other Impellers and guide wheels promoted to the pressure port and experienced a pressure increase corresponding to the number of stages. The partial flow for cooling the motor and lubricating the Plain bearing is branched off on the pressure side after the last impeller and after flowing through the motor again through the hollow shaft, between the steps, led out. Since accordingly no heated partial flow volume on the suction side of the pump flows back, the NPSH values are much more stable in the partial load range. Units in multi-stage design can therefore also be used for significantly smaller conveying capacities be used as single-stage pumps

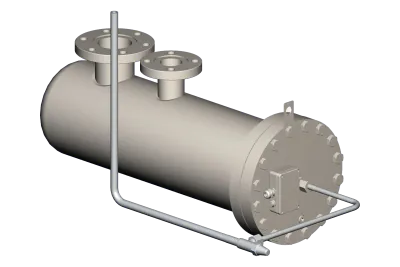

CAM tandem

By arranged on both sides of the canned motor Stages are the highest differential pressures with this unit achievable with a compact design. The complete Flow rate flows through the canned motor and at the same time dissipates the heat lost from the motor. Since accordingly no heated partial flow quantity on the suction side If the pump flows back, the NPSH values are much more stable in the partial load range. Units in tandem design can therefore also be used for significantly smaller conveying capacities be used as single-stage pumps.