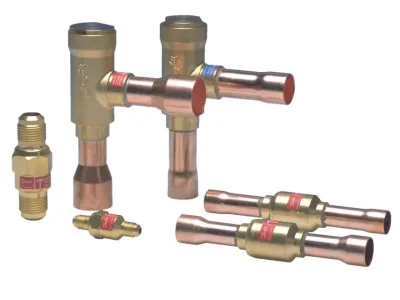

valve stations ICF

Valve stations, ICF 15, ICF 20, ICF 25, ICF 50 and ICF 65

The ICF valve station not only uses the latest technology, its housing also contains various functions that can be used to replace a whole range of conventional mechanical, electromechanical and electronically controlled valves.

Thus, this valve station proves to be advantageous not only during the design phase of a refrigeration system, but also during installation, maintenance and servicing.

The ICF valve stations are suitable for all common refrigerants including CO2. It is delivered completely pre-assembled and has been subjected to a comprehensive test (pressure and function test) at the factory.

Each order number corresponds to an application solution.

Features

- Designed for industrial refrigeration applications with a maximum permissible operating pressure of 52 bar / 754 psig When using the defrost module, a reduced maximum operating pressure applies (see technical data).

- Applicable to HCFC, non-flammable HFC, R717 (Ammonia) and R744 (CO2) The use of ICF valve stations with combustible hydrocarbons is not recommended. • Direct welded connections (no leakage through flanges)

- Optionally with welding ends or welding sockets

- Cryogenic steel case

- Low weight and compact design • Control cone with V-port on the control modules optimize the control accuracy, especially at partial load.

- Modular design Each housing is available with several different connection types and sizes. The valve is maintained by replacing the function modules.

- Side ports for connecting pressure gauges, transmitters, sight glasses, service valves, etc.

- UL Recognition

Specifications

- Refrigerants Suitable for HFC, R717 (ammonia) and R744 (CO2). The use of ICF valve stations with combustible hydrocarbons is not recommended. Exception: The ICFD is only approved for use in onshore applications. Before using with CO2 please contact your local Danfoss office. For more information please contact your local Danfoss sales partner.

- Temperature range Complete ICF platform -60 – 120 °C / -76 – 248 °F Exceptions: ICM: If the ICM module is to be used with liquid refrigerant at a temperature above 75 °C / 167 °F, consult please contact Danfoss. ICFD: When used with ammonia: -50 – 50 °C / -58 – 122 °F at 28 bar / 406 psig If the ICM module is to be used with liquid refrigerant at a temperature above 75 °C / 167 °F, please contact Danfoss.

- Ambient temperature for ICF with ICAD: -30 – 50 °C / -22 – 122 °F • Surface protection The outer surface is zinc chromated to ensure corrosion protection in accordance with DIN EN ISO 2081:2009. Additional on-site corrosion protection is recommended.

- Pressure The ICF valve station is designed for: Max. working pressure: 52 bar g / 754 psig For an ICF valve station with an ICFD module, the maximum working pressure is 28 bar g / 406 psig. If an ICFD module has been installed in a refrigeration system, the test pressure must not exceed 28 bar g / 406 psig. However, this does not apply if the ICFD is temporarily dismantled for testing purposes. The ICFD is only approved in land applications. Before using with CO2 please contact your local Danfoss office. Max. permissible operating pressure for ICFD without float: 52 bar g / 754 psig Opening differential pressure: Please note the respective function module data.

Application example:

Liquid supply line/hot gas defrost line/return line/condensate return

Not all valves are shown. Not suitable for construction purposes.