Pre-insulated piping - Advantages and characteristics

Pre-insulated piping

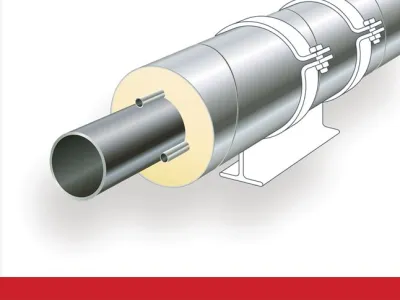

The concept of pre-insulated pipes aims to transport the conveyed media unchanged in the thermal properties. The origin of the structural design lies in the technology of district heating pipelines, whose objective is the transport of heat over long distances. The use of pre-insulated pipes above ground changes the requirements for the product. The climate (wind, rain, snow etc.), installation instructions and technical specifications in the field of plant operation and maintenance are significant influencing factors.

The optimum combination of metallic outer sheath, high-strength and energy-efficient foam insulation and a carrier pipe, which is matched to the properties of the transported product, ensure safe operation, continuous material flow, protection against condensation and a long service life.

The pipe sections are usually delivered in 6m or 12m lengths and are ready to install for on-site assembly. The high mechanical stability of the insulating composite allows the installation of pipe supports on the outer jacket, cold and thermal bridges can thus be safely prevented, an essential factor in the consideration of operating costs.

Thermal properties of pre-insulated pipes

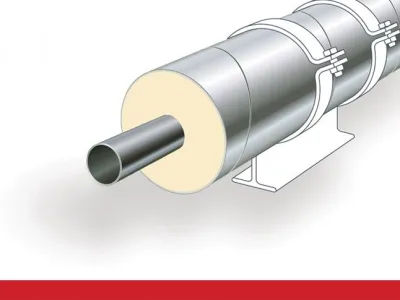

The thermal insulation of pre-insulated pipes consists of a foam structure with self-contained cells. From this material, the pre-insulated pipes get one, two or more layers of insulation. Critical to the design is the operating temperature, the fire resistance, the use in hazardous areas and mechanical influences on the pipe.

The effectiveness of the thermal insulation depends on the foam density. A high foam density of the insulation creates a frictional connection between the medium pipe and the outer jacket, but reduces the insulating effect. In return, a lower foam density increases the thermal insulation effect of the thermal insulation, the mechanical strength is only insignificantly changed. Optimal coordination of these influencing factors is the challenge in creating a specific product solution.

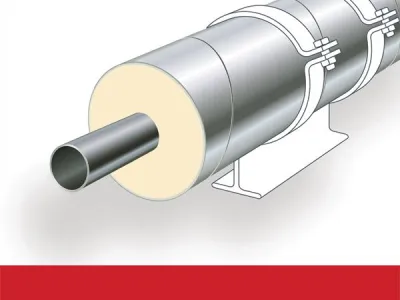

The product concept is supported by the modular principle, the design is determined in close accordance with the requirements of the customer and the company.

The outer sheath is manufactured as a spiral folded sheath with an inner fold, diffusion-proof against moisture or dust and provided with a smooth outer surface.