Condensation Pipe

condensate line

1. Definitions Condensation or condensate

2. Integration into the sewage network

3. gradient

4. wall feedthrough

5. siphon

6. summarize several frozen air coolers

7. heat tracing

8. Insulation

9. material

10.dimension

1. Definitions Condensation or condensate

Everyone knows the phenomenon!

When a cold drink is placed on the table in the summer, water forms on the surface of the glass and runs down it. This creates condensation directly on the cold surface of the glass.

Most of them know this process from everyday life, for example, when operating the air conditioning system of a car. At the evaporator / cooling register of the vehicle creates condensation water, which can be found again after parking in the form of a puddle under the vehicle.

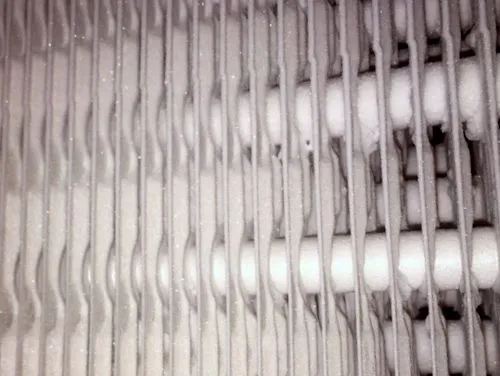

Another example is the freezer compartment of older refrigerators. By repeatedly opening and closing the door, humid outside air flows in. The water in the air gradually settles on the cold walls and freezes. The freezer is increasingly iced up.

While in vehicles the condensation can run freely, you have to initiate the de-icing process with older refrigerators manually and de-icing the freezer.

If air coolers or evaporators are operated below 0 ° C, the condensed water freezes on the cold surface of the heat exchanger. If the air cooler shuts off or is defrosted, the state of matter changes from solid to liquid, causing condensate and condensate.

This is necessary for the following reason: Ice isolated. The more of this builds up on the air cooler or cooling coil, the worse the efficiency of the device or its energy efficiency. Therefore defrosting must be carried out regularly, sometimes even 2-3 times a day.

The resulting condensate / condensation water is discharged via tap water lines controlled.

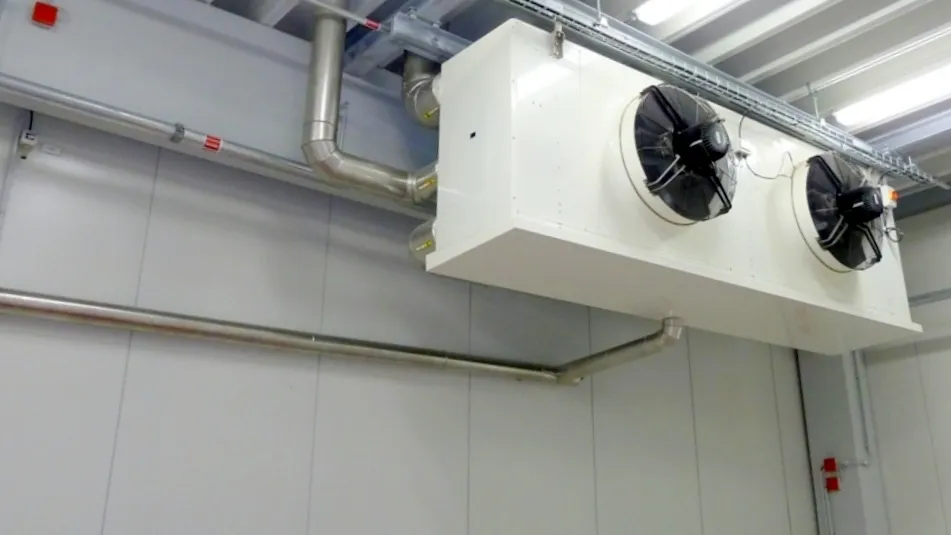

All evaporators and air coolers have a condensation water tank underneath the plate pack, in which the accumulating condensate is collected. In order to ensure that condensate in the tub does not freeze again at low room temperatures, it is heated. Finally, the water is discharged via a permanently installed pipeline from the air cooler into the intended waste water connection of the building.

Often the topic of condensed water with its pipe routes and the connection to the sewage network in the planning of cold storage (building planning) is neglected. The resulting consequential and additional costs, including reduced functionality, can be avoided if the following points 2-10 are taken into account during planning.

2. Integration in the sewage network

In order to avoid unnecessary pipelines or, where appropriate, lifting systems, the condensation water connection points in the sewage network of the building must be taken into account right at the wastewater planning stage. Ideally, the points of attachment are in the immediate vicinity outside the cold room on the side of the air cooler. The accessibility of the installation, the possibility of cleaning and service friendliness must be considered.

3. gradient

The accumulating condensation water must be able to drain freely from the condensation water tank and the pipelines and be discharged with a steady gradient until it enters the sewage network.

If a gradient can not be achieved until the wastewater network is reached, lifting systems and condensate pumps are used to discharge the condensate through plastic pipelines or hoses.

4. wall feedthrough

The integration of the condensate line into the sewage network is largely and ideally always outside the cold room. It is imperative that the pipe penetration through the cold room wall be hermetically sealed after the condensation water pipe has been installed in order to prevent the flow of warm outside air into the cold room.

5. siphon

Each condensation pipe or each pipe system itself must be closed so that no moisture from outside (eg from the air) can reach the cold room or the evaporator. Why: The fan on the evaporator creates a slight negative pressure at the condensation water connection of the drip tray, which can cause the fan to suck in warm outside air and thus also humidity. The result of this process would be a faster icing of the evaporator and the ceiling area immediately before the evaporator.

The closure of the condensate line is made by a siphon (lower arch), similar to a sink drain. This siphon is ideally placed outside the cold room and should be removable for cleaning.

6. summarize several frozen air coolers

If several air coolers are installed in a deep-freeze room and always thaw together, they can be easily combined in a common condensate line.

If air coolers thaw off individually, these should be led out of the room with separate condensate lines. If this is not the case, during the defrosting process, the heat and humidity of the switched-off evaporator can be sucked in by the applied vacuum from a still running evaporator. The resulting consequences, such as icing, have already been described under point 5.

In cold storage rooms with temperatures above freezing, siphons connected directly to the thawing pans can simplify the piping system. The condensate lines can be combined in a sequence.

The interaction of several air coolers is mainly used in industrial refrigeration systems with large evaporators and large condensate lines. In commercial refrigeration systems with condensate lines of a smaller cross section, the influences are negligible.

7. heat tracing

In refrigerated rooms colder than + 2 ° C, the complete condensation water line must be provided with a heat tracing system until it leaves the cold room. The freezing of entrained condensate is thereby prevented. The trace heating should be self-regulating in its temperature. Depending on the room temperature and application, heaters in different capacities (watts) per meter can be used. Depending on the philosophy of the plant manufacturer, the heat tracing systems can be installed from the OUTSIDE on the drainage pipe or also in the pipe. Decisive is the accessibility in case of service. If the heater is defective, it must be exchanged quickly and inexpensively.

8. insulation

Heated condensation pipes must of course be isolated (insulated). If the heat tracing system is mounted from the OUTER to the drainage pipe, the insulation must be completely removed in case of service.

Internal heaters can be pulled out and replaced, for example, at the passage of the fittings, without damaging the insulation of the pipe.

9. material

Basically, the choice of materials is the responsibility of the designer - whether stainless steel, copper or plastic, it is important that they can not corrode. Each plant manufacturer and operator has his personal ideas and opinions about the various materials. In individual cases, hygiene regulations specify the materials to be used.

However, there are some limitations and important considerations that you should consider or apply: Cables with a trace heating, for example, should necessarily consist of copper or stainless steel. A possible fire hazard can be excluded.

Furthermore, the attachment of the condensate line to mention. The number and type of brackets is not to be underestimated: in the case of a plastic pipe, considerably more support points must be set for similar dimensions than for a stainless steel pipe.

Installation and service friendliness also play a role in the laying process. Stainless steel pipe press or plug systems have prevailed in recent years for this purpose.

10. dimension

As with all piping also applies to the condensation pipe: it should not be too small!

It is therefore advisable to calculate the expected amount of condensation water roughly and to carry out the dimensioning of the pipe accordingly.

It should be noted that condensation can drain freely in the pipe. The degree of filling as well as the length of the condensation water pipe until it is integrated into the drainage play a decisive role.

A rough indication of the diameter of the pipe is the connection to the condensation water sump of the air cooler. They should at least continue this dimension. If several air coolers are connected together, the manifold must be made larger accordingly.