Precise media temperature control

Precise media temperature control

Precision refrigeration and air conditioning are essential for many applications and the demand is constantly increasing. An example is the requirement to maintain a temperature of exactly 20 °C in a measuring room in which machine components are measured with an accuracy of fractions of a millimeter. It is important to rule out even the smallest temperature changes so that the measurement results are not falsified. However, applications in the food industry are also conceivable. In such applications, constant air outlet temperatures from the evaporator are the key to success. This can be achieved very well with an electronic suction throttling or media temperature control.

Installation in the suction line

With media temperature control for refrigeration systems with a pipe size of up to 54 mm, an electrically controlled valve (e.g. type "KVS") is installed in the suction line. This valve is equipped with a stepper motor and is controlled with an electronic controller (e.g. "EKC 368"). A fast-reacting temperature sensor (e.g. "AKS 11" or "21") is used as a sensor. This sensor records the actual value of the air outlet temperature of the evaporator and forwards it to the controller. The controller now compares its temperature setpoint with the actual value and decides whether the stepper motor valve should be opened further or closed.

A completely open valve ensures maximum cooling and thus the lowest possible blow-out temperature in the specific load situation. An almost closed valve means a high discharge temperature. Thus, the controller will command the valve to "open the valve" in situations where the setpoint is well below the actual value. This would be the case, for example, with a setpoint of 0 °C and an actual value of 15 °C. Even with a temperature difference of just 1 K, the controller specifies a small degree of opening in order to prevent the controller from overshooting. With such a system, temperature fluctuations of maximum +/- 0.5 K can be expected.

Different transient curves in the starting process

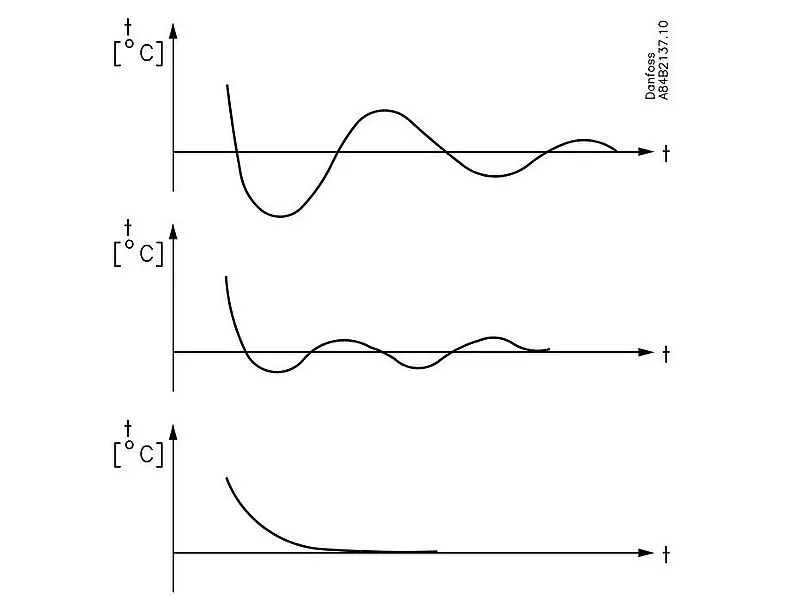

Particular attention should be paid to the start-up process of the controller. The "EKC 368" controller offers three different transient responses to choose from. The first option is to cool down as quickly as possible.

With this setting, a very significant undershoot in the discharge temperature of the evaporator is accepted in order to enable rapid cooling and thus faster reaching of the setpoint temperature. The second option allows only slight undershoot. The last option is a complete omission of blowdown values below the target value during the start-up phase.

This offers the advantage of very gentle cooling of unpackaged goods, avoiding any unnecessary dehumidification. In this case, however, more time must be allowed for reaching the desired setpoint.

service

The controller is operated using two pushbuttons. The controller can be completely programmed using these two buttons, combined with a three-digit display, with all important data being displayed. This means that every fitter on the system can intervene in the control loop or have relevant data displayed. In the controller menu, not only do values that can be set appear, but it is also possible to precisely influence certain processes by intervening in stability and amplification factors.

service

The service menu of the electronic accumulation controller is particularly interesting for the fitter during commissioning or service on the system. All parameter values that begin with "u" indicate actual system values that are important for all types of error diagnostics or for evaluating system states. These values provide information about the system status.

On the one hand, they can be read out quickly and do not have to be laboriously determined with the temperature measuring device. On the other hand, you can see immediately which values the controller assumes as given. For example, it is part of the standard procedure for an experienced fitter to check the control sensor and, if necessary, the defrost sensor in electronic systems before the actual commissioning (with the usual resistance sensors this is quite easy to do with an ohm measuring device. This is how a "PT1000" sensor has at 0 °C a resistance of 1000 ohms) to prevent lengthy troubleshooting if the actual values recorded by the sensor are incorrect. This procedure is no longer necessary when you look at the service menu, because here you can directly assess (if in doubt, measure yourself with the thermometer) whether the value is realistic or not.

Steady electronic valves

The "KVS" is a continuous valve that can be used to avoid even the slightest fluctuations in the evaporation pressure. The "EKC 368" can be used as a P, PI or PID controller. The P control is a standard control according to the deviation (Example: If the air outlet temperature is too high, the opening degree of the valve is always increased at the same speed).

With the PI control, the "reset time" (I component) can be changed individually, which at the same time leads to an adjustment of the reaction speed of the control. In other words: the regulation becomes more nervous or sluggish. Both may be required. The "D component" in PID control also optimizes the control properties in the event of a sudden setpoint change. This control mode is particularly advisable if the system is operated with an external setpoint shift, eg by a higher-level controller.

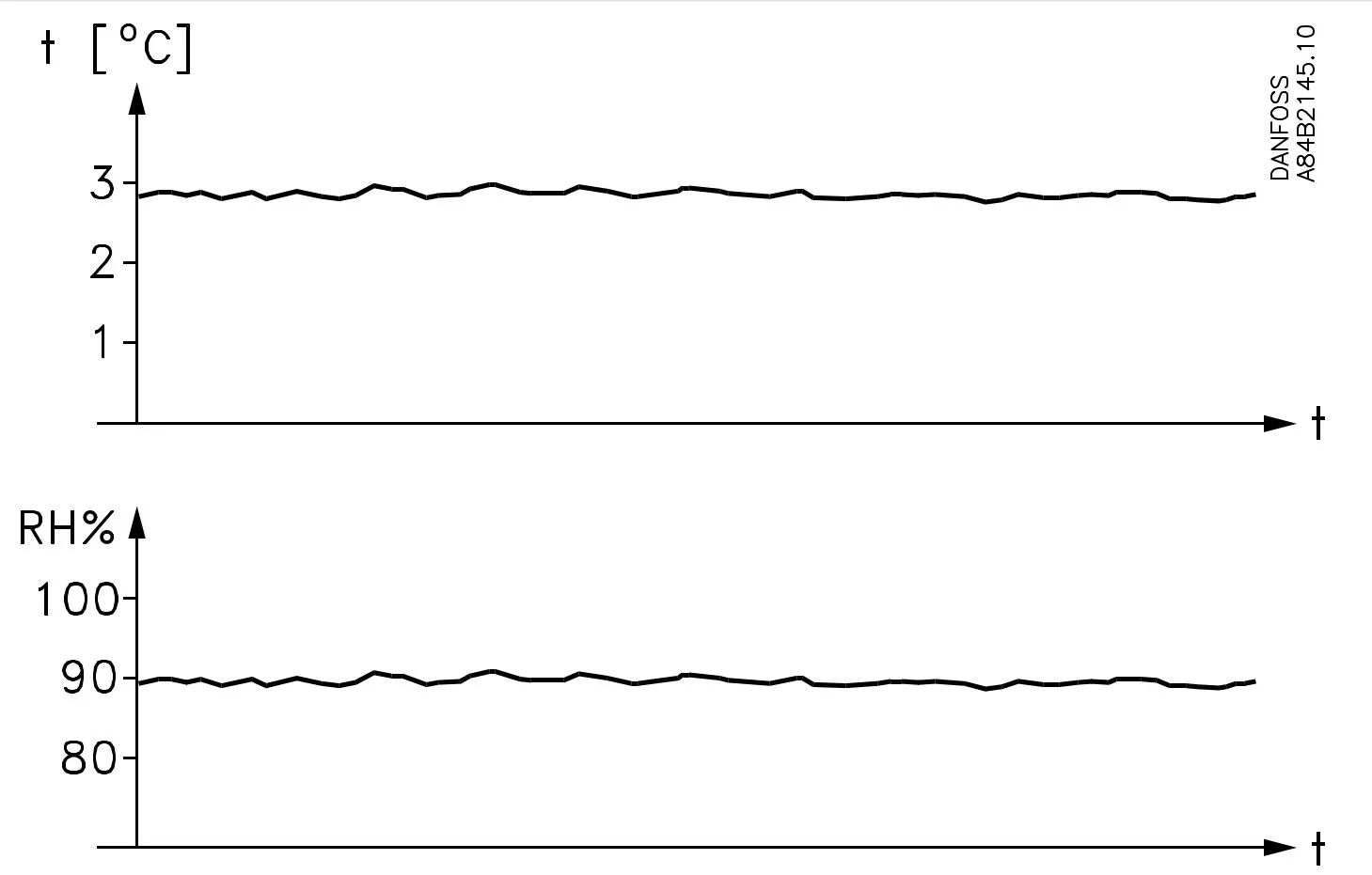

humidity

Refrigeration experts know that the subject of "moisture" plays an important role in refrigeration technology and particularly in the case of unpackaged goods, meat, vegetables and fruit. Due to the constantly high discharge temperature of the "EKC-KVS" system, any undesired dehumidification can be avoided. Nevertheless, there can also be situations in refrigeration systems where dehumidification is required. Indirect measures are usually used for this purpose, e.g. B. changing the evaporator fan stages or the evaporator speed (ie slower fan speed = lower evaporation temperature = dehumidification and vice versa). This point can be influenced directly with an electronic suction throttle system: Simply shift the target value of the air outlet temperature with an external signal from 0 to 10 V and no or hardly any dehumidification is achieved with high evaporation temperature values or high dehumidification with low evaporation. Of course, it also applies here that the dew point must always be undershot for dehumidification. The adjustment of such a system can always be carried out quite easily due to the amount of condensate that is separated out on the evaporator. In addition to storing vegetables and fruit, such a system is also suitable for comfort air conditioning HVAC systems and climate cabinets. The adjustment of such a system can always be carried out quite easily due to the amount of condensate that is separated out on the evaporator. In addition to storing vegetables and fruit, such a system is also suitable for comfort air conditioning HVAC systems and climate cabinets. The adjustment of such a system can always be carried out quite easily due to the amount of condensate that is separated out on the evaporator. In addition to storing vegetables and fruit, such a system is also suitable for comfort air conditioning HVAC systems and climate cabinets.

defrost

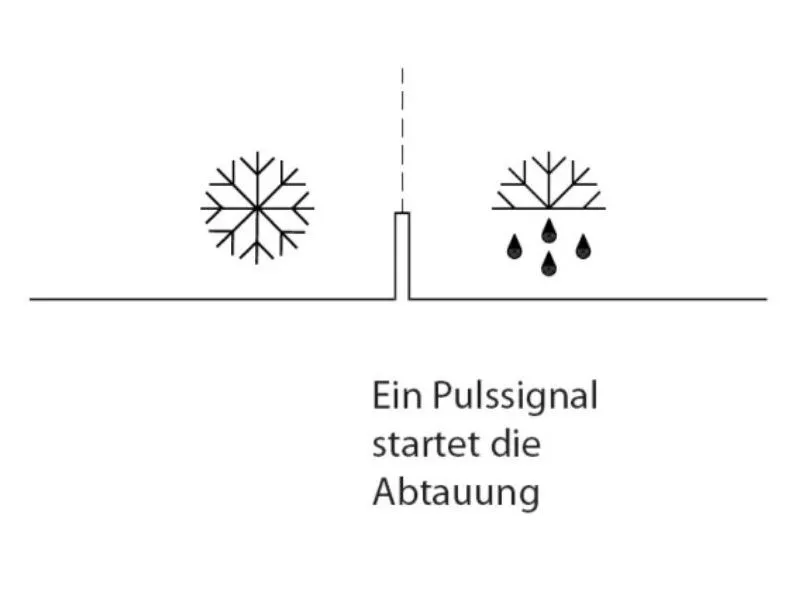

The "EKC 368" also offers the possibility of defrost control through external initiation via an input contact. After defrosting has been initiated, its standard sequence must be defined by setting the controller accordingly. With hot gas defrosting, the "KVS" valve closes during the defrosting process. After the end of defrosting, the "KVS" valve does not open suddenly - like a standard solenoid valve. This is particularly beneficial in terms of relieving the high pressure (and possibly liquid) in the evaporator. In addition, it is not necessary to install an additional valve in the suction line, since the "KVS" can also be used for this shut-off function.

With electrical defrosting, the "KVS" is open. A defrost sensor in the evaporator pack ends the defrost as soon as the temperature of the evaporator pack has reached the temperature set on the sensor. As a safety precaution, a maximum defrosting time can be set in the refrigeration controller, which ends defrosting in the event of a defective defrosting sensor or similar malfunction. After defrosting comes the dripping time. Once this has been completed, the cooling process is restarted. To put it simply, the dripping time simply serves to drain off the ice that has turned to water on the evaporator via the condensate drain.

Solution for large systems

If larger connection sizes than 54 mm are required for the suction line, it is recommended to use a solution with a master valve. This system consists of an "ICS" main valve, a screwed-on pilot valve "CVQ" and the associated controller "EKC 361" (without defrosting functions - the alternative "EKC 367" is equipped with practically the same defrosting functions as "EKC 368"). Here, too, the main valve with pilot is installed in the suction line. The effect of the control and the control-technical functionality correspond to the "KVS-EKC 368" system. However, the "CVQ" uses a pressure cartridge (actuator) to actuate the valve instead of a stepper motor. A "PTC" heating resistor and an "NTC" resistor are installed in this actuator. The "PTC" can be controlled by the controller with 24 V AC, so that the actuator is heated. The valve is closed or opened by this heating. The "NTC" resistor gives the controller feedback on the degree of opening of the valve via the internal actuator temperature. The actual value of this actuator temperature and the current setpoint can be read out in the controller menu of the "EKC 361" ("367"). This is a good troubleshooting tool. If the setpoint (current actuator reference) is, for example, 100 °C and the actual value is also (set/actual value overlap), the control behavior is OK at first glance. If the current setpoint is 100 °C and the actual value is 50 °C, for example, without increasing further, then there is a fault in the controller or in the actuator. In such a case, it should be checked

remote service

In principle, this control system also offers the possibility of remote service. It is possible to equip the controller with a LON module and to record the corresponding data via a master unit or to intervene in the control system from anywhere via a modem connection. This can be done using special software (type “Danfoss AKM”). This means that this media temperature control can be integrated into complex Danfoss control system networks if required.