Hermetic compressors for refrigeration

Hermetic compressors for refrigeration

The nameplate found on every hermetic compressor contains important information for the buyer or user and also for the delivery process.

Among the most important corner data are the type designation of the compressor, the type of refrigerant to be used as well as the electrical connection data.

At the suction port, the gaseous refrigerant is sucked into the compressor, on the opposite side of the compressor housing are the process and the compressed gas connection. The compressed refrigerant is conveyed from the compressor to the condenser via the compressed gas connection. Via the process connection the refrigerant is filled after the installation of the compressor. This is usually done at the end of the assembly line in the factory.

The electrical connection is located on the outside of the compressor. Depending on the model, the starting device is pre-assembled ex works with a suitable plastic protective cover.

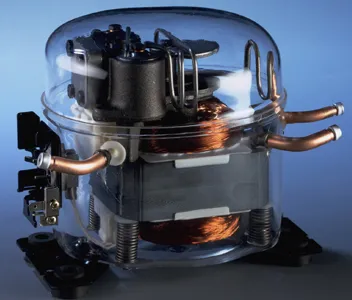

The compressor housing is made of sheet steel, while the upper cover part is welded to the lower housing part. This connection is hermetically sealed, thus ensuring that no refrigerant can escape outside. 4 springs securely hold the mechanical unit (motor, cylinder and valve unit) of the hermetic compressor in the housing in the central position. Outside of the housing are two foot plates for mounting the compressor in the unit.

The engine is a very important part of the compressor, it consists of stator, rotor and power cable. To avoid a Schwingunsübertragung from the engine of the compressor to the compressor housing, the compressor motor is mounted on spring elements. This principle of construction keeps the working noise level low.

The stator consists of an iron package with two copper windings. The package consists of sheets. The windings are well protected, so that any loose wire pieces can not cause any damage. In contrast to the stator, the rotor has an iron core cast around with aluminum.

Each compressor type receives a matching electrical starting device. It serves to start the hermetic compressor; For this purpose, it supplies the necessary power to the auxiliary winding (starting winding) of the motor.

Once the compressor motor has reached a certain speed, the current consumption of the main winding decreases and the starting winding is switched off by the starting device. The motor receives its power via a flexible cable.

The unit of piston and cylinder consists of four parts:

- Block

- outlet pipe

- crankshaft

- piston

The output pipe is fixed on top of the block, at the bottom of the crankshaft is an oil pump. The piston includes a piston pin connected to it by connecting rod.

Inside the block are two outlet chambers that allow the refrigerant to reach the pressure port. The turns of the output tube make this even more flexible.

The crankshaft is fixed to the rotor, it transforms the rotary motion of the engine into piston strokes. Through these piston strokes, the cylinder moves up and down. The movement makes it possible for the refrigerant to be sucked in, compressed and finally pushed out at the pressure connection.

The valve unit includes an outlet valve and a suction unit, both mounted on the main valve plate. The valves open and close the valve discs during the intake and exhaust strokes.

As a result, the compressed refrigerant can reach the outlet chambers. Finally, there is also a silencer to dampen the intake noise. It sits between the suction connection and the suction side of the pump unit.

Components of a hermetic compressor

- 1 housing with connections and foot plates

- 2 upper lid

- 3 block with stator holder

- 4 stator (with screws)

- 5 rotor

- 6 valve unit (screws, cylinder cover, seals, valve plate)

- 7 crankshaft with sleeve

- 8 connecting rod with piston

- 9 Ölansaugrohr

- 10 springs with suspensions

- 11 pressure tube (screw, washer, seal)

- 12 Starting device (PTC starter, cover, strain relief for cables)

"With kind permission of Secop GmbH"