Basics of lubricating greases

In the first two parts of this training, we wrote about the basics of tribology and of lubricating oils. In this part, we want to provide information on the basics of lubricating greases. You are going to learn what a lubricating grease actually is, what types of greases there are, and what kind of benefits they offer in practice.

What is a lubricating grease?

Lubricating greases are compounds which effectively reduce mechanical friction and wear, provided a suitable quality is chosen. From a chemical perspective, these compounds are made up of a lubricating oil, a thickener and additives. Greases are an ideal choice where a friction point is to be effectively protected for as long as possible. Besides providing optimum lubrication, they also shield the component from external influences such as splash water, air humidity and dirt, depending on the individual ambient conditions.

Depending on the individual requirements of a specific application, you may choose between high-temperature, low-temperature, high-speed or heavy-load greases, or those certified as H1.

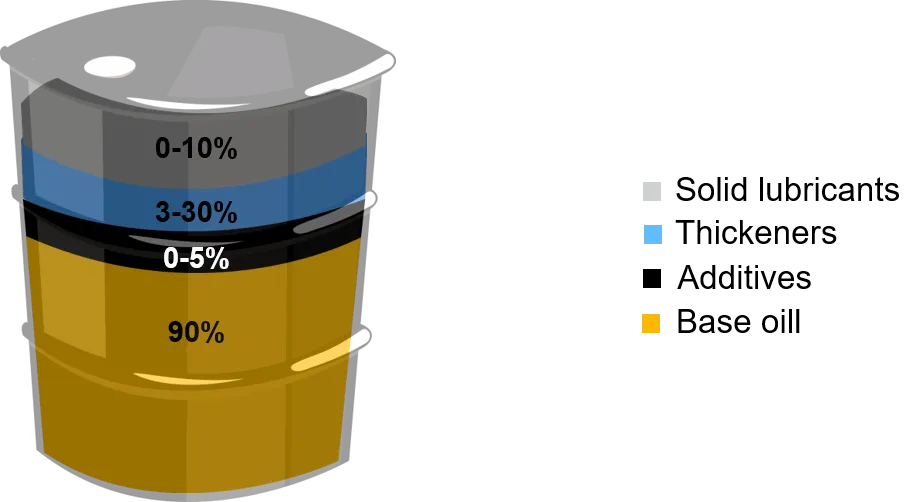

What is the composition of a lubricating grease?

Depending on the intended use and field of application, the formulation of a lubricating grease comprises the following ingredients:

Which base oils are most commonly used for making greases?

- Mineral oil (paraffinic or naphtenic) (MIN)

- Polyalphaolefins (PAOs)

- Ester oils (E)

- Polyalkylene glycols (PAG)

- Silicone oils

- Perfluoropolyether oils (PFPE)

What is a thickener?

Thickeners are substances increasing the consistency (nature and degree of internal cohesion) of a grease. A differentiation is made between metal soap greases and soap-free greases.

What is the function and what are the tasks of a thickener?

- It retains the oil to give the grease its texture.

- It continuously releases oil, providing the friction point with lubricant.

- It contributes to building up a lubricant film.

- It seals the friction point, shielding it against dirt and moisture.

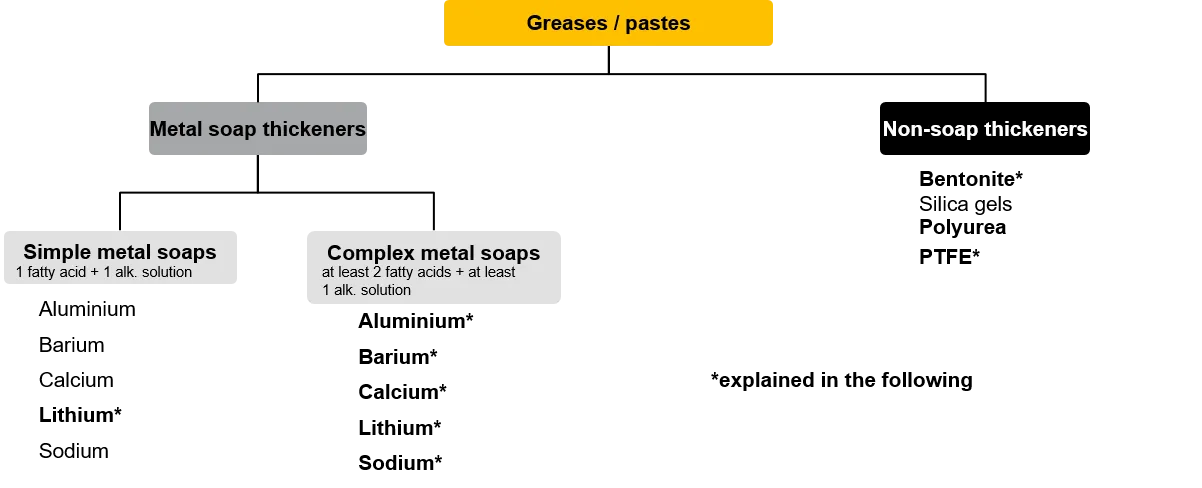

What types of thickener are there for greases?

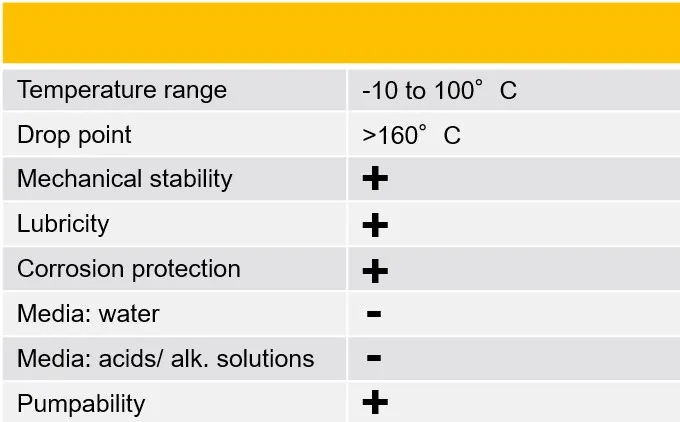

What is a lithium grease?

Lithium greases are made by neutralising a 12-hydroxy stearic acid lithium hydroxide in an oil. Lithium soap greases are often used as multipurpose lubricants. Lithium soap shows the best behaviour of all simple soaps and is used in many applications.

What is an aluminium complex soap grease?

Aluminium complex soap greases show very good resistance to water and good pumpability. They are often used for the lubrication of components and machines in the food-processing industry.

What is a barium complex soap grease?

Barium complex soap greases contain as thickener mixtures of various, mostly organic acids saponified with barium hydroxide. Greases of this type show good resistance to water and steam, good anticorrosive characteristics, a high load-carrying capacity and have a high drop point. They are suitable for both low and high temperatures and are frequently used in high-speed rolling bearings.

What is a calcium complex soap grease?

Calcium complex soap greases contain as thickener mixtures of various, mostly organic acids saponified with calcium hydroxide. These greases have good anticorrosive characteristics, are resistant to water and show a high load-carrying capacity.

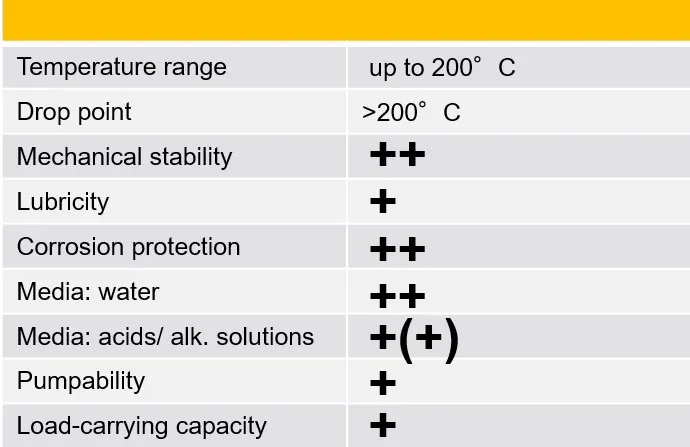

What is lithium complex soap grease?

Lithium complex soap greases are enhanced lithium soap greases offering better stability and high-temperature characteristics. As thickener, mixtures of various, mostly organic acids saponified with lithium hydroxide are used.

What is a sodium complex soap grease?

Sodium complex soap greases contain as thickener mixtures of various, mostly organic acids saponified with sodium hydroxide. Greases of this type show good emulsifying behaviour. They are mostly used as fluid greases in gearboxes.

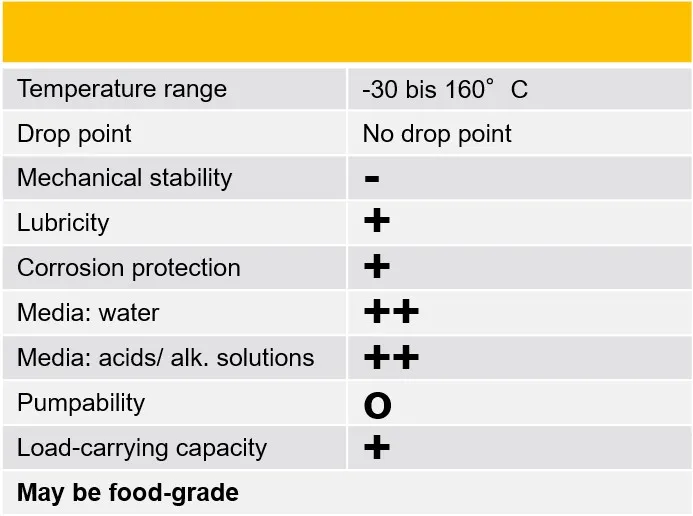

What is a bentonite grease?

Bentonite greases show good high-temperature behaviour. They have no drop point. Depending on the base oil type, they show good low-temperature behaviour.

What is a polyurea grease?

Polyurea are used as grease thickeners that do not form ash. Greases with polyurea thickeners are used for high-end greases with a high drop point.

What is a PTFE (polytetrafluoroethylene) grease?

PTFE greases are used for very demanding technical requirements. They have a wide service temperature range, are resistant to aggressive media, have a high load-carrying capacity. PTFE also offers emergency running properties. Typically, a PFPE (perfluorinated polyether) oil or silicone oil is used as a base oil for PTFE greases.

Which thickeners are intermiscible?

The following table serves for rough guidance. For a reliable determination of oil miscibility, it is always recommendable to have corresponding tests conducted at the lubricant manufacturer.

What does the NLGI grade mean for a lubricating grease?

Lubricating greases are characterised by classifying them into NLGI (National Lubricating Grease Institute( consistency grades according to DIN 51818.

This classification is based on the measured penetration of a standardised cone into the grease acc. to DIN ISO 2137. Since it is not possible to manufacture a grease with always the exactly same consistency, each NLGI grade has a permissible penetration range of approx. 30 units (1 unit = 0.1 mm penetration depth). The next grade follows at an interval of 15 units.

What benefits do lubricating greases offer?

- Less complex component/machine design (sealing)

- Long service life with low maintenance

- In many cases for-life lubrication

- Low consumption

- Better sealing due to grease

Do you wish to acquire more in-depth knowledge of the subjects tribology, lubrication technology and lubricants?

Then the trainings offered by Klüber Lubrication might be an option for you. Twice to three times per year, we offer two-day trainings in Munich. Alternatively, you can order individual trainings tailored to your needs on the subject of "lubrication and lubricants" to be held on your premises.

Do you have any questions or need consulting?

Klüber Lubrication can look back on more than 90 years of experience in the fields of friction optimisation and specialty lubricants. We will be pleased to provide personal advice for your specific requirements regarding refrigeration compressor oils.

This is how you can reach us:

Stefan Zuber

Global Business Team Compressors

Phone: +49-89-78 76 502

Email: Stefan.Zuber@klueber.com

Website: www.klueber.de

Editor and copyright: Klüber Lubrication München SE & Co. KG

Reprints, total or inpart, are permitted only prior consultation with Klüber Lubrication München SE & Co. KG and if source is indicated and voucher copy is forwarded. The data in this document is based on our general experience and knowledge at the time of publication and is intended to give information of possible applications to a reader with technical experience. It constitutes neither an assurance of product properties nor does it release the user from the obligation of performing preliminary tests with the selected product. It constitutes neither an assurance of product properties nor a guarantee of the suitability of the product for a specific application. They do not release the user from from the obligation of performing preliminary field tests with the product selected for a specific application. All data are guide values which depend on the lubricant's composition, the intended use and the application method. The technical values of lubricants change depending on the mechanical, dynamical, chemical and thermal loads, time and pressure. These changes may affect the function of a component. We recommend contacting us to discuss your specific application. Products from Klüber Lubrication are continually improved. Therefore, Klüber Lubrication reserves the right to change all the technical data in this document at any time without notice.

Klüber Lubrication München SE & Co. KG - Geisenhausenerstraße 7 - 81379 München Deutschland

Munich District Court, HRA 46624