Filter driers in refrigeration

General function

Filter dryers are usually installed in liquid lines of dry expansion refrigeration systems and have a dual function there. On the one hand, they are intended to catch coarse dirt particles and copper shavings, but on the other hand also to bind moisture in the system. For this purpose, modern filter dryers are equipped with a dry block of 100% molecular sieve for optimum drying performance and filtration. The filter drier should be replaced with every intervention in the refrigeration system.

drying capacity

When looking at the corresponding data sheets, one repeatedly encounters the term "dry performance". It indicates the amount of refrigerant that can be "dried" by the filter drier at a defined refrigerant and temperature. It is based on a certain moisture content of the refrigerant before and after the drying process. For example, a "DML 53" dryer can deliver 8.5 kg refrigerant R134a at 24 ° C from 1050 ppm to 75 ppm. Incidentally, "ppm" stands for "parts per million", ie particles per million particles, and in this specific case refers to the number of water molecules (H2O) present in the refrigerant per million refrigerant molecules. If the refrigerant charge of the system to be planned has not yet been determined, then the design of the suitable filter dryer can also be carried out after the liquid performance. By "liquid power" is meant the cooling capacity in "kW" for the installation of the dryer in the liquid line.

When looking at the corresponding data sheets, one repeatedly encounters the term "dry performance". It indicates the amount of refrigerant that can be "dried" by the filter drier at a defined refrigerant and temperature. It is based on a certain moisture content of the refrigerant before and after the drying process. For example, a "DML 53" dryer can deliver 8.5 kg of refrigerant R134a at 24 ° C from 1050 ppm to 75 ppm. Incidentally, "ppm" stands for "parts per million", ie particles per million particles, and in this specific case refers to the number of water molecules (H2O) present in the refrigerant per million refrigerant molecules. If the refrigerant charge of the system to be planned has not yet been determined, then the design of the suitable filter dryer can also be carried out after the liquid performance. By "liquid power" is meant the cooling capacity in "kW" for the installation of the dryer in the liquid line.

Practical tip: The ppm values stated before and after drying can be taken over by the plant manufacturer as practicable and, in practice, based solely on the refrigerant and the refrigerant charge of the system.

Choice and size

Thus, a suitable filter dryer can already be designed via the drying or liquid power. In general, the internal volume of the standard dryer is always important. Therefore, it is now common for manufacturers to include the volume of the filter driers in the type designation. In the last example we talked about a "Danfoss DML 53". The "53" is an internal volume of 5 inch3 and the connection size 3 (10 mm). The connection size in this type designation is then divided by 8 to get the corresponding connection (eg "DML 53": connection 3, ie 3/8 and corresponds to 10 mm as metric unit). When doing so, it may be necessary to pay attention to the suffix "s" (eg "DML 82s"), which stands for "solder" (English term for soldering) and thus refers to a solder connection. if the suffix "s" does not exist, it is the flanging variant. Practical tip: If you are forced to use the type of dryer that is currently included in the after-sales service vehicle, you can use the last number of the type designation to select a suitable replacement for the connection size.

Standard and biflow dryer

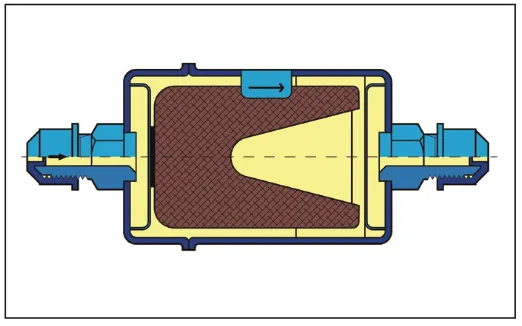

Filter dryers are available in various designs. The standard dryer (eg "DML") is most commonly found in commercial plant engineering. It has a solid core and forms an inseparable unit with the compact housing. These standard dryers are only designed for one flow direction (observe arrow direction on the dryer housing). This is usually completely sufficient. However, if you have a real biflow operation - as occurs in a heat pump with a 4-way reversing valve - you can either arrange two standard dryers in parallel with opposite flow direction and mount a check valve in the corresponding flow direction or equal to them select a biflow dryer ("Danfoss DMB").

Burnout and housing dryer

If a standard dryer is actually required, but the piping connection sizes are already in the range of 22 mm and larger, then the use of a housing filter dryer for replaceable dry blocks is recommended ("Danfoss DCR"). These housing filter dryers are available for operation with one or more solid inserts. The main advantage of this variant is the very easy replacement of the dry inserts without soldering or disassembly of the piping and the moderate service price, as the housing remains in the system and does not have to be bought again. The main field of application of this housing dryer is also the liquid line. However, when using a case dryer as a burn-out dryer (use block insert "48 DA"), the suction line is favored as the installation location. This may be necessary because too much acid has formed due to a water leak in the refrigeration system or an engine fire. Burnout block inserts or filter driers are predominantly made of aluminum oxide, as it is specially optimized for acid absorption. In such a burn-out case, the block insert should be exchanged after certain time intervals and finally a coarse dirt filter element ("Type 48F") should be used at the last exchange. Such burn-out dryers are also available with non-exchangeable inserts for small pipe connections ("Type DAS"). If you want to be aware of the enormous water absorbency and at the same time the high amount of moisture that is bound in the ambient air, in mind, then you can build the following simple experiment. You open a dryer block insert (eg. "48 DM") and put the block on a letter scale. Now note down the weight and note the color of the dry core (take a photo if necessary). One day later, the color of the dryer has darkened considerably and the weight has increased significantly.

FaceSeal and pen dryer

For smaller systems that are difficult for a collector to use, a collector dryer ("Type DMC") can be used. Basically, it can be said that here simply a large housing as a replacement for the collector and a dry core were combined. The world's most common type of dryer - thank the white goods - are Penciltrockner. These pencil dryers are usually copper colored (and made of copper - other types of driers are painted), filled with silica gel beads as a desiccant and can be found in virtually every refrigerator right in front of the capillary tube. Another variant of this variety of driers are the face-seal dryers. For plant manufacturers who deal exclusively with stationary cold, these are real exotic. The face-seal dryer is usually used in the transport refrigeration and commonly referred to as "O-ring dryer". These are standard dryers but with a different thread connection than the flaring equipment. The sealing of the dryer towards the pipe connections is realized with an O-ring and is flat-sealing, as the name "Face seal", literally means "face-sealing", already says.

selection

In order to select the suitable dryer for a specific plant, one orients itself first to the pipe dimension of the liquid line. Since there are usually several filter dryer sizes for a port diameter, the dry performance can be a good further help for the selection. For a quick selection - without further consideration of dry or liquid performance - you should always select the slightly larger dryer. For example, the dryer sizes "DML 83", "DML 163" and "303" are all provided with a 10 mm crimp connection. The coarse choice should tend to be the size "163" or "303". The decision for a slightly larger dryer is never a real disadvantage (except the slightly longer length).

pressure drops

In general, always pay attention to the resulting pressure drops when selecting components. In the case of filter driers, this is usually not necessary because they have only a marginal pressure drop when used with the appropriate piping. Practical tip: If you find a filter drier in an existing plant that condenses or even forms ice despite the usual condensing temperatures (eg 45 ° C) (and without a subcooler installed) after the filter drier on the pipe surface, then the Dryer with high probability added with dirt particles. In the case of measuring connections before and after the dryer, the service manometer then displays a correspondingly high pressure drop when checking. in such a case, only the replacement of the dryer helps.

Practical tip: A filter drier with O-ring and the addition FS (eg "DML305 (FS)") is a face-seal dryer.