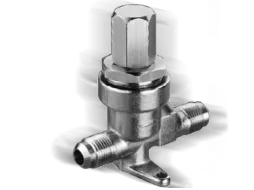

Filter dryer type HM

Proven quality to protect your system!

TRIPLEX® FilterTrockner:The house brand of HANSA Automotive - with flared connection or for soldering.

MULTIPLEX FilterDryer:The same long-lasting quality in the dimensions and designations commonly used today. Available with flared connection, for screwing with O-ring seal and of course also for soldering.

Filter dryer type HM

Filter driers HM are used in liquid lines in refrigeration/air conditioning systems and in vehicle air conditioning systems.

Advantages

- HM dryers are characterized by a very high drying capacity, abrasion resistance and vibration resistance.

- The drying takes place over molecular sieve and aluminum oxide. The proportion of aluminum oxide binds acids.

- Even with a high degree of soiling, the drying effect is fully retained.

- Fine filtration prevents the passage of solid particles.

- The dryer housing is scale-free brazed and welded under protective gas.

- The surface is phosphated and powder coated.

Cleaning dryer type HM

In hermetic systems, acids, oil resins, oil sludge, water and the finest carbon particles can form in the refrigeration cycle. These impurities are found as oil residues in the evaporator, condenser, etc. Finest particles and catalytically accelerate the harmful chemical reactions. The contaminants are often not removed simply by replacing the oil and the refrigerant.

A cleaning dryer in the suction line filters out these impurities and binds them chemically and adsorptively.

Advantages

- Faster and easier installation.

- Complete chemical and adsorptive binding of impurities, acids and water using various desiccants.

- Optimum filtering with a coarse filter and thick-walled block insert with a very large filter surface.

- Minimum pressure loss due to very large filter surface.

Technical Notes - Cascade cleaning and drying

- Pre-cleaning of coarse particles (larger than 0.1 mm Ø) from the steam-oil mixture using a fine-mesh wire screen (mesh size 0.08 mm).

- Chemical binding of the acids by aluminum oxide. Adsorption of oleoresin and sludge by alumina.

- Fine filtering of the particles and simultaneous adsorption of water through a compact molded body made of highly activated molecular sieves and aluminum oxide.

- Particularly high moisture absorption.

- Maximum operating pressure 55 or 60 bar.

- Cleaning dryers are suitable for all refrigerants (except NH3 and those containing NH3).