*C-EJECTOR

*c-Ejector is used to increase efficiency in CO2 booster systems. In combination with a high-pressure valve, three different types of gas ejectors and two types of liquid ejectors can be combined as required.

FEATURES

Efficiency increase of 15-30% possible (compared to a booster system with flash gas bypass)

Lower compressor capacity required (smaller or less compressors)

Individually adaptable to each application and each capacity

Air conditioning and / or heat pump evaporator can be integrated

Extended running time of the parallel compressor even at low outside temperatures

High reliability (no moving or rotating components)

Short payback time (depending on system size)

Technical specifications

- refrigerant R744 Max.

- operating pressure 120 bar

- Temperature of medium -50°C ... + 150°C

- Ambient temperature -10°C ... + 50°C

- Material Stainless steel

- Weight 1.3 kg

FUNCTION – PRINCIPLE OF OPERATION

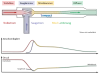

*c-Ejector utilizes the expansion work present in the refrigerant to suck in a different partial flow and convey it to a higher pressure level.

The CO2 exiting the gas cooler at high pressure is accelerated in the jet nozzle. As a result, the static pressure decreases. The flow emerging from the nozzle has a lower pressure than the suction pressure of the NK stage.

Optionally, gas or liquid can be drawn off from the suction side of the NK compressors.

Both partial flows mix in the mixing chamber.

In the diffuser, the flow is decelerated again, which causes a pressure increase to medium pressure level. After the diffuser, the mixture is fed into the medium pressure separator.