Innovative solutions for optimizing server cooling. Learn more and reduce energy costs.

Applications

Energy Saving

Efficient Cooling for Data Centers

With the exponentially increasing volume of data and the associated heightened demand for centralized computing power, more and more powerful data centers are being operated. The servers, storage devices, and network components require energy and constantly generate heat that needs to be dissipated. Traditionally, the energy consumption of data

Contents

Product Ad

Image

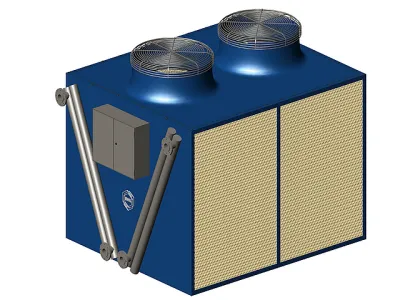

Industriewärmepumpen mit Schraubenverdichtern für industrielle Anwendungen mit maximaler Heizleistung von 1800 KW und einer maximalen Temperatur von +95°C

Jobs

Mounting

Mechanic/Welder (m/f/d) at GEA

We are looking for three mechanics/welders (m/f/d) at our Berlin location.

Image

GEA Refrigeration Germany GmbH

Berlin, Germany

Fulltime

Project management refrigeration technology

Commercial Employee Order Processing in Engineering (m/f/d)

To strengthen our team, we are looking for a commercial employee to handle engineering projects as soon as possible.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fitter refrigeration technology

MTA Refrigeration Technician (m/f/d) in Customer Service for Baden-Württemberg

To strengthen our team for the Stuttgart region, we are looking for you as a Refrigeration Technician (m/f/d) for our customer service.

Image

MTA Deutschland GmbH

Nettetal, Germany

Fulltime

Get in Touch with the Author

If you have any questions or would like additional information, the author of this article is happy to assist you. Simply use the options below to get in touch directly.

Related Products

Image

Designed to cool water with minimal operating costs thanks to two operating modes.

Image

The TOPAZ is a cooler with an adiabatic cooling section before the air intake. This allows the air temperature to be reduced, if necessary, at higher ambient temperatures. The adiabatic pre-cooling...

Image

with an outstanding performance potential thanks to the interaction between wet and dry cooling

Related Articles

Enhancing Defrosting Efficiency in Cold Storage Facilities

Optimizing Cooling Operations and Saving Energy During Defrosting with Mechanical Solutions

12°C – Hot Gas Defrosting for Evaporators

Efficient Defrosting in Industrial Freezer Warehouses

Efficient Cooling for Data Centers

Innovative solutions for optimizing server cooling. Learn more and reduce energy costs.

Efficient Cooling for Data Centers

Innovative solutions for optimizing server cooling. Learn more and reduce energy costs.

Efficient Cooling for Data Centers

Innovative solutions for optimizing server cooling. Learn more and reduce energy costs.

PUE - Power Usage Effectiveness in Data Centers

PUE Value - Power Usage Effectiveness Explained Briefly

Energy Saving without Structural Changes

Reducing energy demand increases the margin on your product.

Energy Saving without Structural Changes

Reducing energy demand increases the margin on your product.

Difference between Control and Regulation

Explaining the technical difference between control and regulation in simple terms